-

21

-

© STULZ GmbH, Hamburg

-

21

-

>20°

>5°

D>200mm

R>300mm

>5°

D> 200mm

>5°

R> 300mm

H 2m

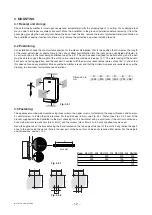

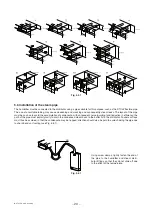

According to the position of the steam distributor, the path of the pipe may use one of two following solutions:

1. rise upwards with a vertical section of at least 300 mm, followed by a curve with a minimum radius of 300 mm and finally

a downwards section with a constant gradient of no less than 5° (see Fig. 5.6.2);

2. for short paths (less than 2 metres), curves with a minimum radius of 300 mm, followed by a rising section with a gradi-

ent of no less than 20° (see Fig. 5.6.3).

Fig. 5.6.2

Fig. 5.6.3

IMPORTANT WARNING:

The length of the steam pipe should be less than 4 m.

5.7 Installation of the condensate return pipe

Due to the re-condensation of the steam produced, condensate forms inside the steam pipe and the distributor that must

be removed to avoid gurgling and a reduction in efficiency. The condensate is drained by gravity using a flexible pipe that

is suitable for the purpose. The use of unsuitable tubing may cause weake ning and cracking with consequent steam leaks.

To avoid the release of non-condensed steam from the condensate pipe, a drain trap must be made by looping part of the

drain pipe. The end of the condensate pipe can be connected to the nearest drain pipe, with a minimum slope of 5° to assist

correct downflow (see Fig.5.6.2). If the distance of the distributor allows, the pipe may be connected to fitting C, supplied,

to be screwed onto the top of the humidifier, in order to drain the condensate back into in the supply tank of the boiler (see

Fig. 5.6.3).

IMPORTANT WARNING:

For the unit to operate correctly, the drain trap must be filled with water before starting the humidifier.

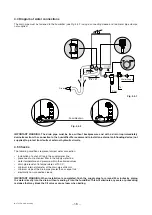

5.8 Checks

The following conditions represent correct installation of the steam pipe:

• the position of the steam distributor complies with the instructions provided in this chapter, the steam outlet pipes are

aimed upwards and the distributor has an upwards incline of at least 2°;

• the end of the pipes are fastened to the fittings using metal pipe clamps with fastening screws;

• the curves in the tubing are sufficiently wide (radius > 300 mm) so as to not cause bending or choking;

• the steam pipe has no pockets or traps for condensate to form;

• the paths of the steam and condensate pipe comply with the instructions provided in this chapter;

• the length of the steam pipe is no greater than 4 metres;

• the gradient of the steam pipe is sufficient to allow correct dragging of the condensate (> 20° for the upward sections,

> 5° for the downward sections);

• the gradient of the condensate pipe is at least 5° at every point;

• the condensate pipe always follows a downwards path and features a drain trap (filled with water before starting opera-

tion) to avoid steam being released.