55

PREVENTIVE MAINTENANCE

Pump wear is directly affected by such things as the abrasive qualities, pressure and temperature of the

liquid being pumped, this section is intended only to provide general recommendations and practices for

preventive maintenance. Regardless of the application however, following a routine preventive maintenance

schedule will help assure trouble-free performance and long life from your 80 series pump.

Record keeping is an essential component of a good preventive maintenance program. Changes in suction

and discharge gauge readings (if so equipped) between regularly scheduled inspections can indicate problems

that can be corrected before system damage or catastrophic failure occurs.

The appearance of wearing parts should also be documented at each inspection for comparison as well.

Also, if records indicate that a certain part (such as the seal) fails at approximately the same duty cycle, the part

can be checked and replaced before failure occurs, reducing unscheduled down time.

For new applications, a first inspection of wearing parts at 250 hours will give insight into the wear rate for

your particular application. Subsequent inspections should be performed at the intervals shown on the chart

below. Critical applications should be inspected more frequently.

Содержание M2-H

Страница 2: ...2 This page left blank intentionally ...

Страница 13: ...13 ...

Страница 18: ...18 M2 H Identifying Your Machine Components Location of Tags and PIN Plates ...

Страница 19: ...19 SECTION II Description Care and Maintenance ...

Страница 31: ...31 SECTION III Set up and Installation of Unit in Detail ...

Страница 33: ...33 SECTION IV Operating the M2 Unit ...

Страница 41: ...41 SECTION V Troubleshooting the M2 Unit ...

Страница 44: ...44 SECTION VI Periodic Maintenance Repair Information ...

Страница 49: ...49 SECTION VII OEM Repair Information ...

Страница 62: ...62 ...

Страница 63: ...63 ...

Страница 64: ...64 ...

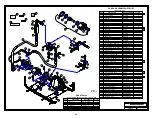

Страница 68: ...68 SECTION VIII Parts Manual ...