MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it [email protected]

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

If the above conditions are met the test will start by opening the output O1 (valve V1 closed in testing) and maintaining

the output O2 closed so that the valve V2 will remain open. The duration of the test valve is set via the parameter “

test

duration”

in the configuration user interface, after the test of the first valve, after 5 seconds it will proceed to the tests

of the second valve in a similar manner (activate O1, O2 deactivated). In case a leveling command is activated (up

command active without speed signal within 5 second), the test is repeated. If during the second attempt a leveling

command is activated again the test failed. The alarm is signaled by the fault relay and the lighting of the LED

indicators. After a switch on/off of the NCBM01 the alarm remain activated until the reset button is pusher for at least

5 seconds. If, during the test one of the following commands:

door open

or

down

or

up

followed by the

speed

within

5s, the test is suspended.

If a frequency daily tests is set, the device has a time-out for the execution of the test of one hour. If the test is not

performed within 1 hour an alarm is generated. If it is set the tests frequency of one hour, there is no time-out

The parameters for the handling of activation delay of the valves, during normal elevator operation, are configured

using the masks "Valve sequence", "down valve closing delay", "down valve opening delay", as described in the

previous paragraph.

Thirty seconds before the execution of the test and for the whole duration of the same, the output TW (test warning)

will remain active to signal the imminent execution of the test. This function is useful to signal to the control cabinet the

test coming and to perform the commands necessary for the preparation of the test : door closing, lowest floor...

2.4 Bucher I-VALVE signal control

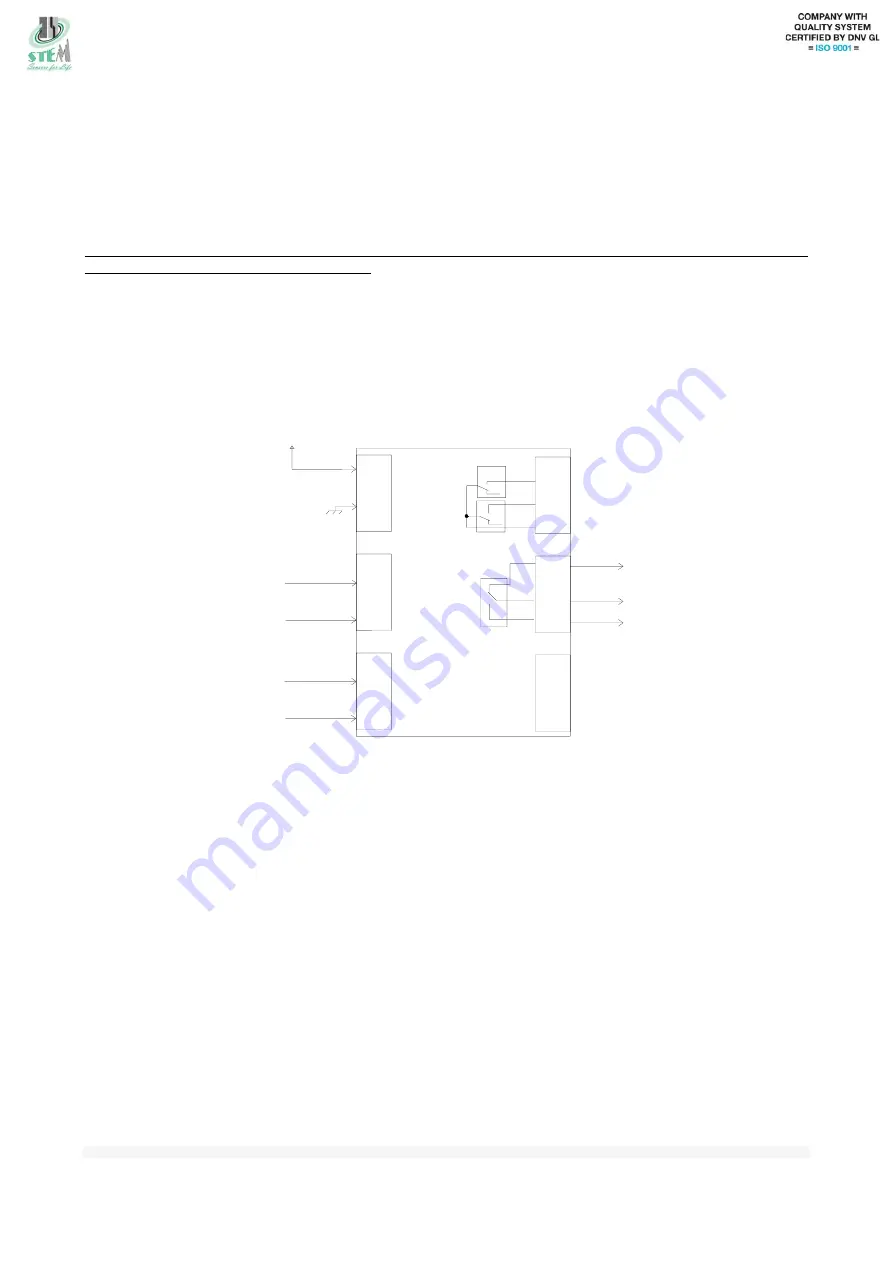

FIG. 2 Electrical scheme connection for hydraulic lift

The configuration Bucher I-VALVE allows to control the timing of the SMA signal when the travel signal is changing

the state. As indicated in the valve manual, the system detects the

error1

and

error2

:

Error 1 : when travel command goes from high level to low level, the SMA signal should change the state from 0.1s to

1s after the travel signal change, if the timing is not respected error1 has to be detected

Error 2 : when travel command goes from low to high level, the SMA signal should change the state within 0.1s after

the travel signal change, if the timing is not respected error2 has to be detected

If the error is detected the Fault relay will change state according to the relay polarity selected in the SW configuration

•

FNO, in case of alarm FNO, CF is closed

•

FNC, in case of alarm FNC,CF is closed

Led 3, Led4 and led5 continues to signal the state of the SMA and TRAVEL commands even if NCBM is in alarm

The alarm will be maintained until a manual reset will be performed.

JP1

T2

D2

D1

JP3

V1

PO2

JP2

T1

A2

A1

PO1

V2

J1

FNC

J2

CF

S1

S2

J3

FNO

K2

Fault Relay

K1

PT2

PT1

A3

A4

NCBM 01

+24VDC / L1(AC)

TRAVEL

COMAND

SMA

SIGNAL

CO

TW

O1

O2