D2X

D2X Operator’s Manual

15

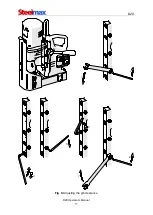

3.6. Drilling

Use the gear switch to set the speed based on the following table.

Tool

Hole diameter

Rotational speed*

[rpm]

[mm]

[in.]

Annular cutter

12

–35 0.47–1.38

400 (gear II)

36

–50 1.38–1.97

200 (gear I)

Twist drill bit

3.5

–13 0.14–0.51

400 (gear II)

14

–23 0.55–0.91

200 (gear I)

* for sharp tool and mild steel with a shear strength

R

m

< 500 N/mm

2

(70,000 psi),

such as for instance St0 (S185), St3S (S235JR), or St4W (S275JO)

Steel with a shear strength

R

m

= 500

–700 N/mm

2

(70,000

–100,000 psi), such

as

for

instance

St5

(E295),

18G2A

(S355N),

or

45

(C45),

requires

lower rotational speed.

If the speed is selected too high or low for the shear strength and the type/diameter of

the tool, the tool will wear faster or be unable to drill the hole.

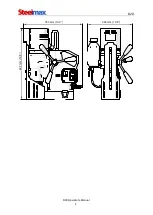

Start the motor using the green MOTOR button and slowly rotate the spoke

handles to the left to lower the tool to the workpiece, and begin drilling.

When using annular cutters, drill holes in one pass.

When using drill bits, drill holes with diameters of

18

–23

mm (0.71

–0.91’’) in two

passes. Drill a first hole using a drill bit with the 70% diameter of the hole size desired,

and then drill again using the bit with diameter equal to the hole size desired.

After

the

drilling

depth

exceeds

40

mm

(1.6’’),

apply

the

cutting

fluid

manually into

the drilling area.

After the hole is made, retract the tool from the workpiece and press the red

MOTOR button to stop the motor. Before moving the machine to another drilling spot,

set

the MAGNET switch to the position ‘O’ to turn off the electromagnetic base.

After the work is finished and the motor is stopped, switch to the opposite gear

(for instance from gear I to II), and then run the machine

for

a

while

without

load,

which will improve lubricity. Next, turn off the motor and the electromagnetic base,

unplug the machine from the power source, clean chips and excess coolant from the

machine and tool, and then remove the machine from the worksite.

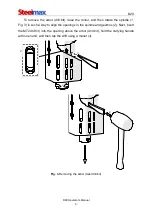

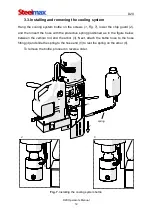

Tighten the bottle cap, close the valve, and then press the pilot pin to expel the

coolant remaining within the cooling system. Before inserting the machine into

the

tool

box,

remove the bottle, and then wear gloves to remove the tool from the holder.

When the annular cutter goes through the workpiece, the slug

core is expelled from the cutter with a significant force.