D2X

D2X Operator’s Manual

13

3.4. Control system of the electromagnetic base holding force

The D2X drilling machine incorporates a holding force control system to monitor the

clamping

of

the

electromagnetic

base

to

the surface. The force value depends on

several factors, such as type, thickness, flatness, and roughness of the surface,

presence of paint, rust or other contaminants, fluctuations of supply voltage, and the

wear of the electromagnetic base bottom.

If the holding force falls below a safe operating value, the control system will not

allow the machine to operate. Additionally, the system will prevent the startup of the

motor

on

a

surface

thinner

than

5

mm

(0.2’’)

because

such

thickness

does not provide

sufficient holding force. In such a case, the holding force will be only about 25% of

the force attained on a standard 22-

mm (0.87’’) flat plate.

If the motor does not continue operation after the green MOTOR button is pressed

and released, it means that the control circuit is operating properly and preventing

further drilling because the holding force is too low.

3.5. Preparing

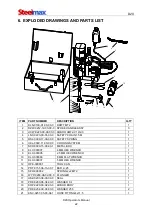

Before beginning, clean steel parts, especially the MT2 shank, from anti-corrosion

coating used to preserve the machine for storage and transport.

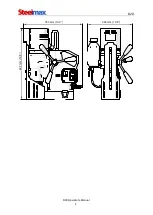

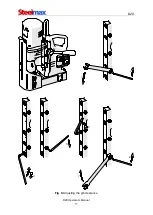

Screw the spoke handles into the feed shaft. The feed shaft can be installed at

the opposite side of the drilling machine to allow working in places hard to reach or

using the machine by a left-handed person.

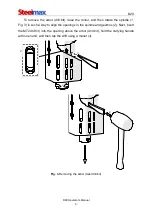

Select the proper annular cutter or drill bit based on the hole size desired. Next,

use a clean and dry cloth to wipe the spindle, arbor (drill bit), and cutter, and then

install

the

arbor

(and

then

the

cutter)

or

the

drill

bit as described before.

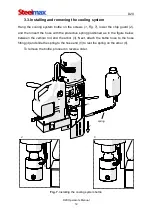

Position the machine on a flat ferromagnetic surface (some types of stainless and

acid-proof steel do not conduct magnetic flux) with a thickness of at least 8 mm (0.3

’’).

The workpiece must be clean, without rust or paint that decrease the holding force of

the electromagnetic base.

Connect

the

drilling

machine

to

the

power

source, and set the MAGNET switch to

the position ‘I’ to turn on the clamping of the electromagnetic base.

Use the safety chain to prevent the machine from dropping and avoid possible

injury to the operator if the machine loses magnetic clamping in case of a power loss.

To protect the machine, attach it to a fixed

structure

by

fastening

the

chain

to

the

lugs