ENGLISH

14

14

Do not cut bigger materials than the allowed by the

maximum capacity of the tool.

After turning on the tool “ Switch (On)”

softly push the

tool onwards until reaching the workpiece, then slowly

increase the required pressure to produce the least

possible amount of debris.

Never use this tool without stop for over 31 minutes.

Warning!

After completing the cut, lift the tool’s head,

switch it off and wait until the disc has completely stopped

before leaving the tool.

Never work in hazardous areas whith flammable

solids, liquids or gases.

Debris and hot fragments may

cause an explosion.

This tool was specifically designed for ferrous metals

and aluminum only.

Do not try to cut wood, masonry or

any flammable material.

Do not use lubricants or liquids on the tool.

Some metal coatings may be toxic

. Be extra careful

when working with this kind of materials, ask your provider

for further instructions.

This tool was designed for certain tasks only

. Do not

use this tool for other purpposes or tasks than those that it

was designed for. In doubt always ask your provider about

the applications and uses of this tool before working with

it.

Metal dust and debris are sharp and hot and may cause

injuries.

Never touch them bare handed, use a magnet or

another tool to remove them.

This tool is for wet-dry cutting. Designed for ferrous and

non ferrous materials.

This saw uses l 400rpm or more discs. Wood and steel

cutting is not advised as it will drastically reduce the disc

and tool’s lifespan.

Unboxing

Carefully extract the tool and all its accessories. Keep all

the components around until you are sure they all properly

work with the tool.

Do not use the tool until you have fully read and understood

the contents of this user manual.

Illustrated components descriptions

1. Lower guard

2. Adjustable front clamp

3. Detachable rear clamp

4. Upper guard

5. Spindle guard

6. Debris deposit

7. Split nut

Disc placement and removal

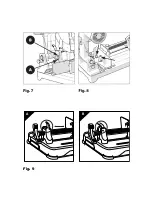

RELEASE the CUTTING HEAD

The cutting head will automatically lift up once the lower

lock is released.

Releasing the head from the lower lock:

- Carefully press down the cutting head.

- Remove the lock from the head and fix it on its external

position (Fig. 1) Allow the head to lift up.

If you encounter any difficulties:

- Carefully move the head up and down.

- Completely remove the hook lock and spin it 1/4 to fix it

on its external position.

Note: When the tool is not in use, we recommend locking

it on it’s lower position.

Disc removal

WARNING: Plug off the tool from the power source

before following this steps.

Use a disc that fits the tool requirements. Make sure

its maximum speed suits the tool.

WARNING:

Avoid touching the disc teeth as they may cause

injuries, use gloves.

Make sure the cutting head is lifted up.

- Release the screw that holds the spindle protection and lift

it up to expose the axis (Fig. 2)

- Secure the tool pressing the axis lock button. (Fig. 3)

Use the provided hex key to loosen the screw. (Fig. 4)

Note: The screw is inverted, spin it clockwise to tighteng it

and counter clockwise to loosen it.

- Remove the axis screw, the washer and the guard to use

it later.

- Change the lower protection to the upper protection

spinning it with your hand. (Fig. 5)

- Remove the disc, leaving its inner edge on working

position.

Disc placement

Use a sutiable disc according to the “recoil” section.

Warning

: Avoid touching the disc teeth as they may cause

injuries, use gloves.

- make sure every component is clean and free of debris.

- Install the disc inserting the inner edge on the axis, making

sure the arrow printed on the disc matches the same direction

on the tool carter. (Fig. 6)

- Reinstall the carter, washer and inverted screw.

- Place the spindle guard pressing the safety button.

- Tighten the axis screw using the hex key provided.

- Put back the spindle protection and fix it tightening its screw.

- Make sure you released the spindle lock moving the guard

manually.

- Make sure to remove the hex key and store it in a safe place

for future uses.

- Check that everything is working as intended, specially the

lower guard by moving up and down the cutting head.

Содержание TD355B

Страница 2: ...4 5 1 6 2 3 7...

Страница 3: ...A B Fig 9...