EN

25

4 . Electrical connection

4 .1 General notes for electrical connection

The electrical connection should only be performed in a de-energized state by authorized

skilled personnel. The safety outputs can be used directly for wiring in the safety-relevant

part of the user control. For requirements in PL e/category 4 according to EN ISO 13849-1,

the safety outputs of the safety sensor or the sensor chain are to be evaluated with the

same category.

Note

To ensure safety, both safety outputs must always be evaluated. Since the

diagnosis output is not a safety output, it must not be used for safety-relevant

signaling and control functions.

4 .2 Requirements for a downstream evaluation

Two-channel safety input, suitable for p-switching sensors with normally open function.

Possible evaluation units:

• SSP Safety Simplifier

• SSP safety relay S Series

• ReeR MOSAIC M1

If the process guard locking with safety function is linked to a relay or non-safe control

components, a new risk assessment must be carried out. The process guard locking with

safety function tests its safety outputs by cyclic shutdown. A cross-circuit detection in the

evaluation unit is therefore not necessary. The test pulses of the OSSD signals must be toler-

ated by the evaluation. The switch-off time of the process guard locking with safety function

is additionally extended depending on the cable length and the capacity of the cable used.

4 .3 Safety controller configuration

The two safety outputs can be connected to the inputs of a safety controller under the

following conditions:

• The input must be suitable for clocked safety signals (OSSD signals).

• The device generates its own test pulses on the safety outputs.

• A downstream control unit must tolerate these test pulses, which can have a length

of up to 0.3 ms.

• Do not use a control unit with test pulses or switch off the test pulses of your control unit.

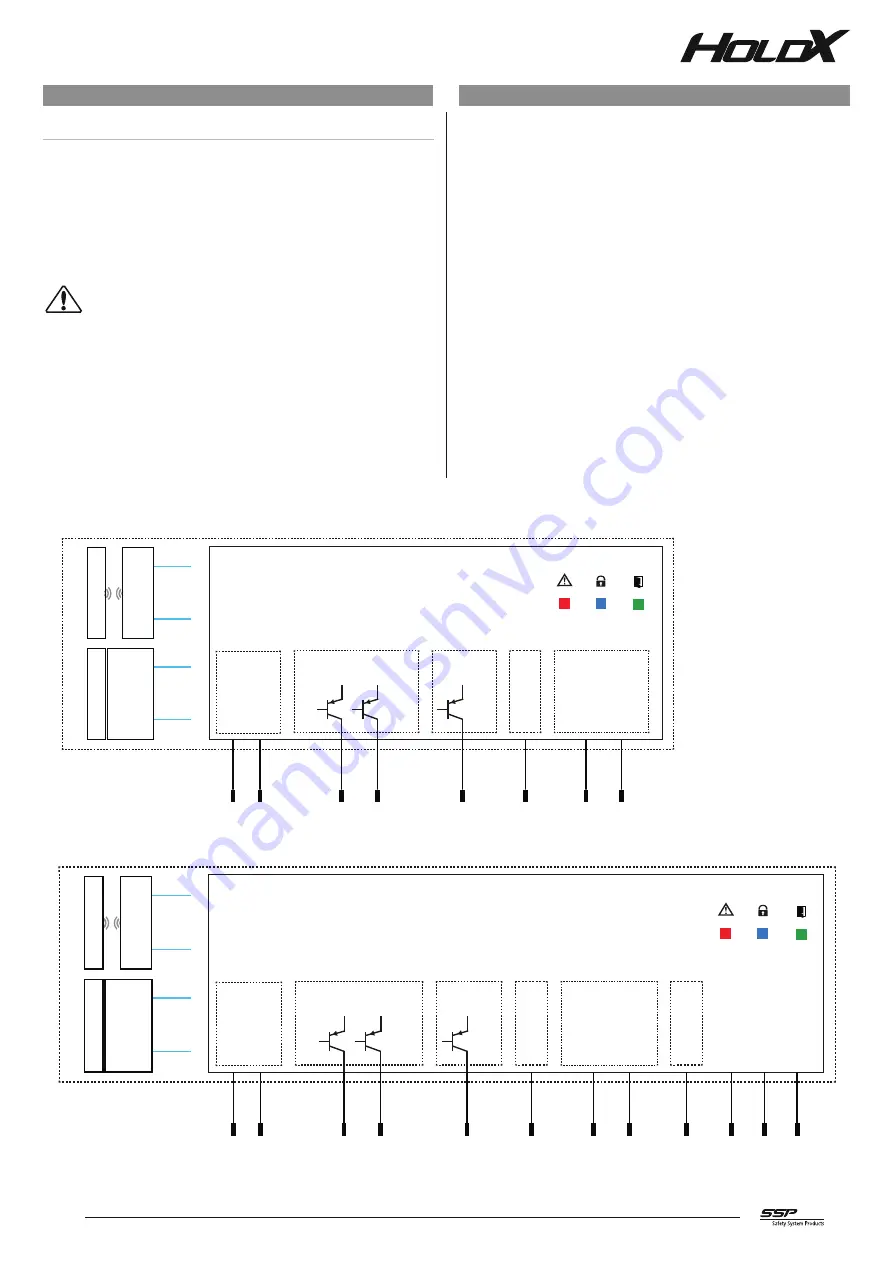

4 .4 Electrical connection diagram

Fig.13:

Safety outputs

power

supply

Saf

et

y sensor

coded

M

ag

net

A

nchor pla

te

Ac

tua

tor

OSSD1 OUT

+24 V

DC

GND

OSSD2 OUT

Diag

nosis OUT

1

3

4

7

Safety inputs

OSSD1 IN

OSSD2 IN

2

6

5

M

ag

net IN

8

HOLDX RS1-P8-...

HOLDX RL1-P8-...

LED diagnosis

Error

Gate

Lock

HOLDX RS1 standalone 8-pin pigtail without reset function

Fig.14:

Safety outputs

power

supply

Saf

et

y sensor

coded

M

ag

net

A

nchor pla

te

Ac

tua

tor

OSSD1 OUT

+24 V

DC

GND

OSSD2 OUT

Diag

nose OUT

1

3

4

7

Safety inputs

OSSD1 IN

OSSD2 IN

2

6

10

11

12

5

M

ag

net IN

8

Reset

9

HOLDX RS1-P12-...

HOLDX RL1-P12-...

LED diagnosis

Error

Gate

Lock

HOLDX RS1 standalone 12-pin pigtail with reset function manual reset