16

4.2 Pilot Air Filter - Element Replacement -

Models 370 scfm and larger

4.2.1 Frequency of replacement -

Pilot air filter contains a filter element which should be changed yearly

or sooner if pressure drop across cartridge prevents valves from actu-

ating. Pilot air pressure must not drop below 60 psig (4.2 kgf/cm

2

).

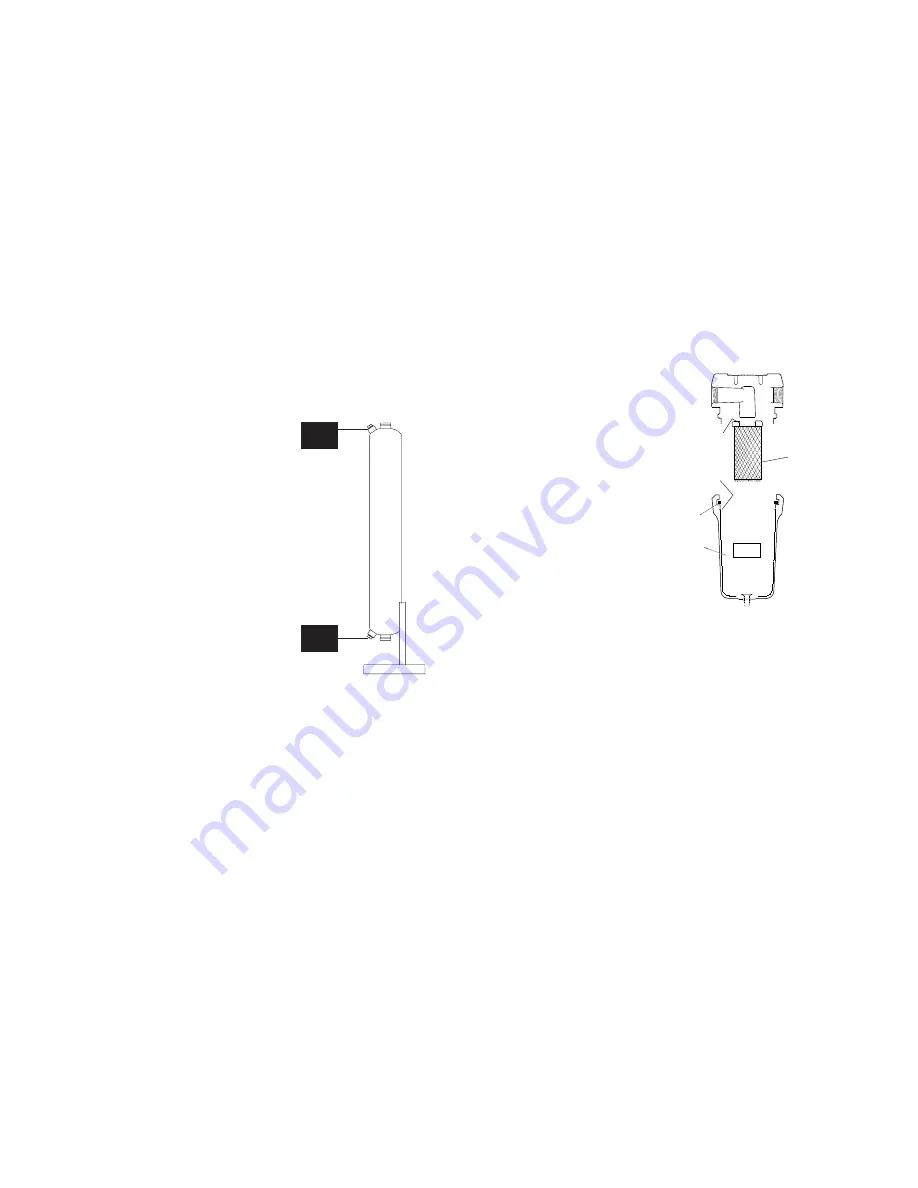

4.2.2 Procedure for element replacement.

Follow instructions supplied with replacement element.

WARNING

THIS SEPARATOR IS A PRESSURE CONTAINING DEVICE. DEPRES-

SURIZE BEFORE SERVICING. IF SEPARATOR HAS NOT BEEN DEPRES-

SURIZED BEFORE DISASSEMBLY, AN AUDIBLE ALARM WILL SOUND

WHEN THE BOWL BEGINS TO BE REMOVED FROM THE HEAD. IF THIS

OCCURS, STOP DISASSEMBLY, ISOLATE AND COMPLETELY DEPRES-

SURIZE SEPARATOR BEFORE PROCEEDING.

1. Shut off air supply.

2. Depressurize Dryer.

3. Remove bowl.

a. Push bowl up, turn bowl

1/8th turn to your left,

and pull bowl straight down

4. Clean filter bowl

5. Replace element

a. Pull off old element and

discard

b. Make certain o-ring inside

top of replacement element

is in place and push element

onto filter head.

NOTE: Make certain o-ring is generously lubricated.

6. After making certain that bowl o-ring is in place, reassemble bowl

to head.

NOTE: Wave spring ends should be pointed down to prevent the wave

spring from interfering with reassembly.

4.3 Fuse Replacement

4.3.1 Fuses are located on board in electrical enclosure. See figure

3B for Standard Control Board and 3C for Automatic Purge Sav-

ing System.

4.0 MAINTENANCE

FIGURE 4B

Element O-ring

Replacement

Element

Bowl O-ring

Wave Spring

Spacer

WARNING

The heatless desiccant dryer is a pressure containing device. Depressurize

before servicing. (See Section 3.3)

4.1 Desiccant Replacement

NOTE: The use of the correct replacement desiccant is necessary for

proper dryer operation. Never use hygroscopic salts of the type com-

monly used in “deliquescent” type dryers.

4.1.1 Frequency of desiccant replacement

Desiccant should be replaced whenever the required dew point cannot

be maintained while the dryer is being operated within its design condi-

tions and there are no mechanical malfunctions. Refer to section 5.0 for

troubleshooting hints.

NOTE: Desiccant life is determined by the quality of the inlet air. Proper

filtering of the inlet air will extend the life of the desiccant.

Typically desiccant life is 3 to 5 years.

4.1.2 Procedure for Desiccant Charge Replacement

4.1.2.1 Depressurize and de-energize the dryer. (See section 3.3)

4.1.2.2 Remove the fill and drain plugs

from desiccant tower and drain

the spent desiccant. Place a

container at the base of the

vessel to collect the desiccant.

If necessary tap the sides of the

vessels with a rubber mallet to

loosen desiccant.

4.1.2.3 Replace the drain plug using

teflon tape sealant or equivalent.

4.1.2.4 Fill the desiccant drying tower as

full as possible with dry desic-

cant. Do not tamp desiccant.

4.1.2.5 Replace the fill plug using teflon

tape sealant or equivalent.

4.1.2.6 Repeat this procedure for the

other tower.

4.1.3 Insuring desiccant dryness

4.1.3.1 Replacement desiccant is shipped in air tight containers. Keep

the covers on these containers tightly closed until use to avoid

moisture contamination. If desiccant is exposed to air it can be

heated in an oven at 400°F (204°C) for four hours before use,

or the procedure in 4.1.3.2 can be used.

4.1.3.2 If the dryer is not refilled with dry desiccant, it will be necessary

to operate the dryer with an inlet flow rate of less than 50% of

maximum to dry the desiccant. To do this, set the Economizer

Switch for 100%, and the purge pressure for 45 psig. (3.2 kgf/

cm

2

)

4.1.3.3 Purge mufflers should be changed annually.

4.1.3.4 Valve(s) should be checked annually.

DRAIN

PLUGS

FILL

PLUG

FIGURE 4A

DRAIN

PLUGS