Form 44201129

Oct 2019 rev A

11

9.0)

SYSTEM EXHAUST MANIFOLD

1. All exhaust manifold tube is manufactured to a standard diameter. All joint connections, on all sizes of

fittings, push fit into the relative tube and should be sealed using high temperature silicone sealant. No

locking bands are required.

2. Tube joints should be made as follows:-

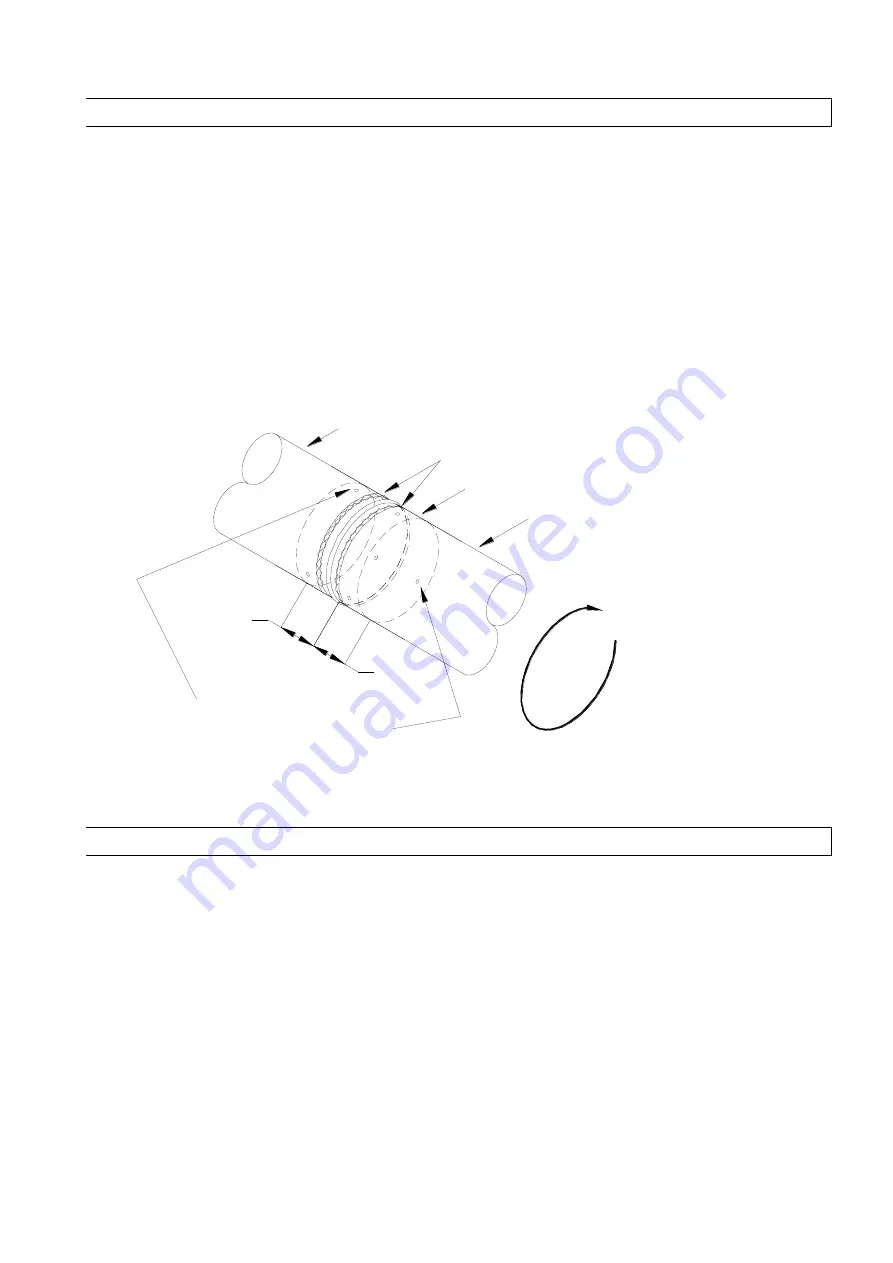

Cut tube to length required, remove all burrs and wipe off any oil or grease with a clean rag. Apply a bead

(3mm) of high temperature silicone sealant around both the outer end of the fitting and the inner end of the

tube. Insert the fitting into the tube up to the raised bead around the fitting. (50mm) using a slight rotary

action to spread the sealant (Fig. 11).

NOTE: The sealant remains workable for approximately 5 minutes after application.

3. Finally, secure the joint by drilling 3 equally spaced holes (Ø5.5mm) through both the tube and fittings (one

hole to be at 12 o’clock to prevent possible leakage of condensate) and rivet the tube to the fittings Ø5 x 6

pop rivets.

Fig. 11

10.0)

COMMISSIONING

Inspect the installation and ensure that the appliance, exhaust manifold and any combustion air ducting has

been assembled and installed in accordance with the relevant section of these Installation, Service and

Operating Instructions.

It is essential that all new pipework installations are purged and tested for soundness with a suitable leak

detection fluid prior to attempting to ignite any appliance. This work should be carried out in accordance with

National or Local regulations.

N.B. DO NOT TEST FOR SOUNDNESS BY USE OF NAKED FLAMES.

Spiral wound manifold

push fit fittings with raised bead

3mm bead of high temp. silicone sealant

Spiral wound manifold

3No. equally spaced holes Ø5.5mm

for Ø5mm pop rivets.

(one hole to be at 12 o'clock

to prevent condensate leakage)

50mm

50mm

Insert fitting using

slight rotary action

to spread sealant

Содержание ADL25-HB

Страница 17: ...Form 44201129 Oct 2019 rev A NOTES...