23

Loading Film Sheets

Op

er

a

tio

n

3

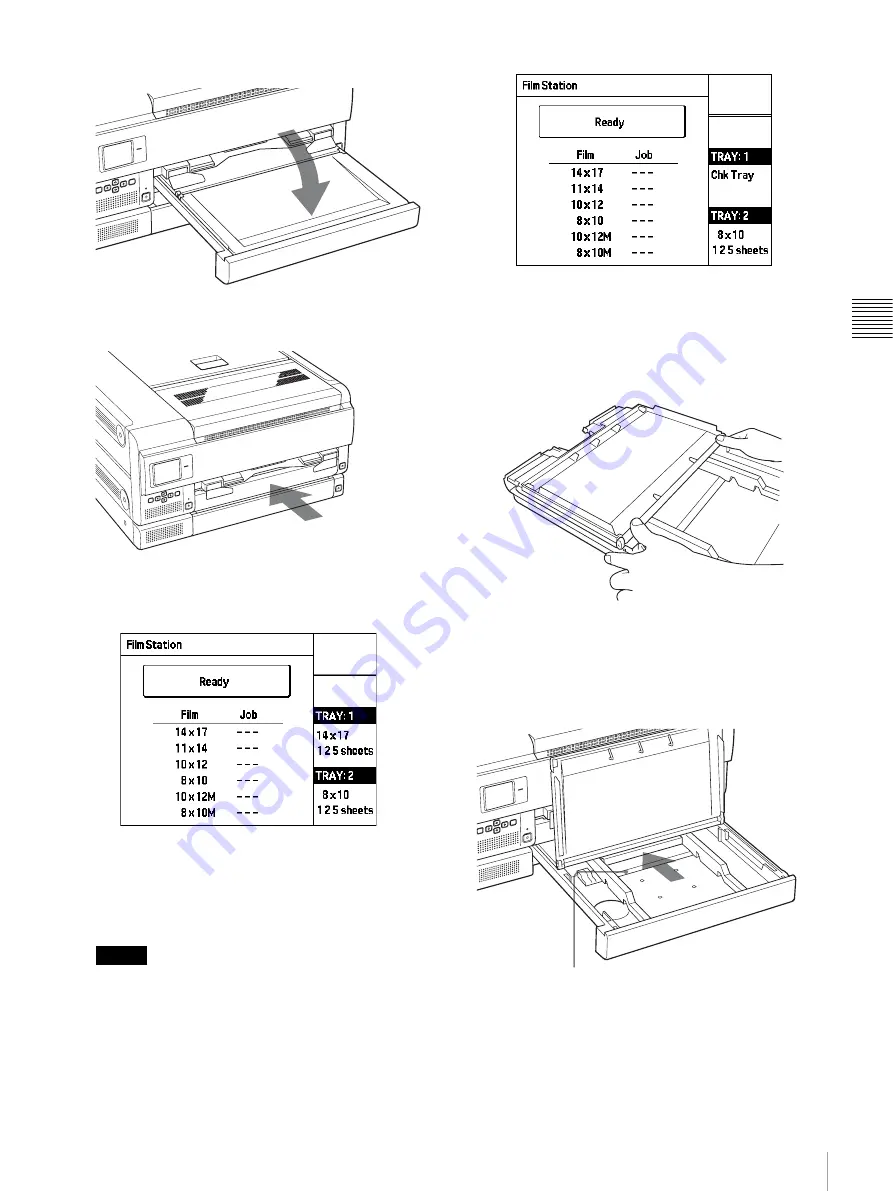

Close the film tray cover.

7

Insert film tray 1.

After a few seconds, the film tray is locked and the

following message appears on the LCD.

To calibrate the printing density

We recommend calibrating the printing density of the

loaded film by referring to “Calibrating the Printing

Density” on page 32.

Notes

• Be sure to insert film tray 1 all the way into the unit

until it stops. When the film tray is not inserted

completely and the film sheets are not loaded

correctly, the following message appears on the

LCD.

• If you try to insert the film tray into the wrong film

tray side, you cannot do so because the stopper

prohibits you from inserting the tray all the way in.

If the cover of the film tray comes off

Remove the film tray and re-attach the cover.

When using size 8 × 10 (about 202 × 253 mm) film

Insert the film sheets securely as the printing surface

protection sheet passes over the stopper located in the film

tray.

Stopper

Содержание FilmStation UP-DF750

Страница 8: ...8 For the customers in Taiwan only ...

Страница 56: ...56 Mammography Quality Control Guide Miscellaneous ...

Страница 66: ...Sony Corporation ...