GRW

Installation

3

SolutionAirGroup.com

|

GRW - Manual

Mechanical Installation

Location

GRW units are approved for both indoor and outdoor

installations.

The GRW unit is designed for complete field serviceability

including the removal of evaporator and condenser coils.

Also, the air-cooled condensers, if equipped, require clear

unfettered airflow for proper operation. The submittals

include recommended service areas for these features,

these areas should be accessible, open, and free of other

equipment.

In addition, for roof top installations, consideration should

be made to ensure that normal service traffic to the unit

will not cause damage to the roof system. If the equipment

is located on a sloped roof or a raised structure, the

platform should be sufficiently large to allow for the unit to

be safely serviced.

Clearances

The GRW unit is designed to be field-serviceable, which

includes the coils, filters, fans/motors, dampers, and

electronics. Refer to the submittal engineering drawings for

the locations of access doors and safety/service areas, and

ensure there is sufficient clearance for safety, inspection,

and service.

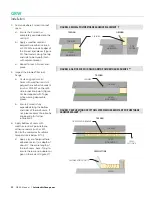

Roof Curb or Base

GRW units can be installed on a concrete housekeeping

pad, sleepers or a roof curb. The unit must be adequately

supported with either field supplied sleepers or structural

metal. Details of the required support can be found in the

submittals. Make sure that the unit supports are the correct

dimensions and that they are flat and level.

Check that the housekeeping pad is the correct dimensions

for the unit and that it is flat and level. If there is an external

condensate drain check that there is enough height for the

required condensate traps and that a means of removing

the condensate is located nearby.

Generally the curb is shipped in advance of the unit

delivery. It should be installed along with any required

ductwork prior to unit installation. Where a roof curb has

been supplied in knocked-down condition, absolute care

must be taken to make sure that all corners are square, and

that finished dimensions exactly match those provided on

the drawings. If this is not done, problems could arise with

the installation and seal of the unit to the curb.

First insure that the top of the curb is level and flat, shim

the curb to the roof deck as required. Then, check diagonal

dimensions prior to securing the curb to ensure that

dimensional integrity has been maintained during shipping.

Finally, complete roofing in accordance with accepted

roofing practices.

Prior to the installation of the unit, check that the curb

is the correct dimensions for the unit and that the curb

profile is correct (this is especially important if the curb

is not supplied by SolutionAir). Curb ductwork and

condensate drains that pass down through the curb must

be installed by installing contractor prior to unit placement.

Gasketing or other forms of sealant must be used around

the curb perimeter and at the duct connections. When

the curb is supplied by SolutionAir, a neoprene gasket is

included. Prior to the installation of the unit, secure the

gasket to the mating surface of the curb by peeling the

backing off the gasket material and applying adhesive-side

down.

NOTE:

To minimize sound transmission, only cut openings

in roof deck for ductwork penetrations. Do not cut out the

entire roof deck within in the curb perimeter.

Содержание GRW

Страница 29: ...GRW Notes 27 SolutionAirGroup com GRW Manual ...