Lit. No. 74256, Rev. 02

18

February 15, 2020

OPERATING THE SPREADER – CAB CONTROL

Error Codes – Spreader Operation Stopped –

continued

Code De

fi

nition

Possible Cause

Suggested Solution

CP

Not applicable to tailgate

spreaders. See suggested

solution.

Not applicable to tailgate

spreaders.

Reset the control by pressing the ON/OFF

button. If

CP

code continues to display, contact

authorized dealer.

Ct

Control is hot.

Cab temperature is too high.

Control overheated.

Turn spreader OFF and allow control to cool o

ff

.

EF

Excessive drive faults.

Too many

HO

and/or

SO

error codes; hopper module

overheating.

Control times out for 60 seconds.

Ensure that auger and/or spinner are not jammed.

HO

Hopper overload –

software trip.

Drive system has high current.

Material is jammed.

Auger is damaged.

Inspect auger; clear material jam.

HO

.

Hopper overload –

hardware trip.

HP

Hopper power issue.

No motor present.

Hopper drive motor is not

connected.

Possible motor defect.

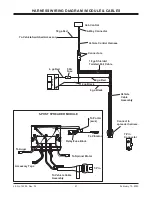

Check connections to the auger drive motor

(P–FEED and FEED–N posts on the module and

studs on the motor).

Replace the motor.

Lb

Low battery. Hopper

module is sensing <6V.

Bad connection or low battery.

Snowplow or other vehicle

power use may be driving

down voltage.

Voltage is measured at the hopper module, so

Lb

code may indicate cable voltage loss. Check

battery, alternator, and connections.

nC

No connection.

Spreader not connected to

vehicle harness.

Connect vehicle and spreader harness.

Check vehicle harness fuse.

Inspect spreader and vehicle harnesses.

Check module.

OH

Overheating.

Spreader module is too hot.

Spreader module malfunction.

Accessories wiring/function

problem.

Drive motor overload.

Allow a cool-o

ff

period—60 seconds or longer.

Check for loose harness connections.

Check accessory connections. Check integrity of

accessory wiring and harness.

Clear jammed material.

Contact authorized dealer.

OH

.

Overheating module –

microprocessor.

rS

Reset of spreader module.

Power loss to module detected

on startup.

Reset the control by pressing the ON/OFF button.

Check vehicle harness and battery connection.

SO

Spinner drive overload –

software trip.

Material jammed in

chute/spinner area.

Spinner shaft is damaged.

Inspect spinner and spinner drive components for

alignment and condition. Check for damage to

bearings, shafts, and sprockets.

Adjust and replace parts as required.

SO

.

Spinner drive overload –

hardware trip.

SP

Spinner power issue.

No motor present.

Spinner drive motor is not

connected.

Possible motor defect.

Check connections to the motor (SPIN and GND

posts on the module).

Replace the motor.

Содержание V-Pro 32200

Страница 2: ......

Страница 4: ...Lit No 74256 Rev 02 4 February 15 2020...