HRL

Series

Specific Product Precautions 3

Be

sur

e

to read t

h

is

bef

or

e

h

andlin

g

t

he

p

roducts

.

Refe

r to th

e

b

a

ck

c

o

ve

r

f

or sa

f

ety instructions. For temperature control

equipment precautions, refer to the “Handling Precautions for SMC Products” and the “Operation Manual” on SMC website:

https://www.smcworld.com

Piping

Caution

1.

Regard

i

ng the

ci

rculatin

g

f

lu

i

d

pi

ping,

c

ons

i

der

careful

l

y the suitability

f

or tem

p

erature and

ci

rculating fluid.

If the operating performance is not

sufficient,

the pipings may burst

during operation. Also

,

the use of corrosive materials such as alu-

minum or iron for

fluid

contact parts

,

such as

piping,

may not only

lead to clogging or leakage in the circulating

fl

uid circuit but also

refrigerant leakage and other unexpected problems. Provide

protection against corrosion when you use the product.

2.

Selec

t the piping

p

ort s

ize

w

hich

can

excee

d the

rated flow

.

For the r

ated fl

ow

, re

fer to the pump capacity table.

3

.

Whe

n t

igh

t

e

n

i

n

g

at th

e

drain

p

ort o

f

t

h

is

p

rodu

c

t,

use a pipe wren

c

h to

c

lamp the connection ports.

4.

For the

ci

rculating fluid piping connection, install a

drain pan and wast

e

water collection pit just in case

the circulating fluid may leak.

5.

Th

is

p

roduct series ar

e

c

onstant-tem

p

eratur

e

fl

uid

ci

rculating ma

c

hines with

b

uilt-in tanks.

Do not install equipment on your system side such as pumps

that forcibly return the circulating fluid to the unit. Also

,

if you

attach an external tank that is open to the air

,

it may become

impossible to circulate the circulating

fluid

. Proceed with caution.

Mounting/Installation

Caution

3

.

Ref

er to the Operation Manual

f

or this

p

roduct, and

s

e

cur

e

an

i

nsta

ll

ation spa

ce

that

i

s nec

e

ssary

f

or

the maintenance and ventilation.

<Ai

r-cooled refri

g

eration>

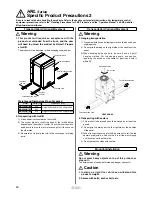

1. The air-cooled type product exhausts heat using the fan that is

mounted to the product. If the product is operated with insuf

fi

-

cient ventilation

,

ambient temperature may exceed 45

°

C

,

and

this will affect the performance and life of the product. To pre-

vent this ensure that suitable ventilation is available (see below).

2. For installation indoors

,

ventilation ports and a ventilation fan

should be equipped as needed.

ero

m r

o

m

m 0

00

2

800 mm or more

800 mm or more

800 mm or more

400 mm

or more

Ventilation

Required installation space

for ventilation and

maintenance

HRL -A -20

3. If it is impossible to exhaust heat from the installation area in-

doors

,

or when the installation area is conditioned

,

provide a

duct for heat exhaustion to the air outlet port of this product for

ventilation. Do not mount the inlet of the duct

(flange)

directly to

the air vent of the

product,

and keep a space larger than the di-

ameter of the duct. Additionally

,

consider the resistance of the

duct when making the air vent port for the duct.

<Heat radiation amount/Required ventilation rate>

Model

Heat

radiation

amount

[kW]

Required ventilation rate [m

3

/min]

Differential temp. of 3

°

C

between inside and outside

of installation area

Differential temp. of 6

°

C

between inside and outside

of installation area

HRL100-A -

Approx. 18

305

155

HRL200-A -

Approx. 35

590

295

HRL300-A -

Approx. 45

760

380

24