Design

Warning

1. This catalog shows the specifications of a single

unit.

1) Check the speci

fic

ations of the single unit (contents of this

catalog) and thoroughly consider the adaptability between

the user

’

s system and this unit.

2) Although the protection circuit as a single unit is installed,

prepare a drain pan, water leakage sensor, discharge air

facility, and emergency stop equipment, depending on the

user

’

s operating condition. Also, the user is requested to

carry out the safety design for the whole system.

2. When attempting to cool areas that are open to the

atmosphere (tanks, pipes), plan your piping system

accordingly.

When cooling open-air external tanks, arrange the piping so

that there are coil pipes for cooling inside the tanks, and to

carry back the entire flow volume of circulating fluid that is

released.

3. Use non-corrosive material for

fluid

contact parts of

cir

culating fluid.

Using corrosive materials such as aluminum or iron for fluid

contact parts such as piping may cause clogging or leakage in

the circulating

fluid

circuit. Provide protection against corrosion

when you use the product.

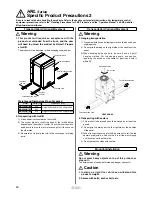

Selection

Warning

Model selection

For selecting a model of thermo-chiller, it is required to know the

heat generation amount of the user

’

s equipment. Obtain the heat

generation amount, referring to the “Cooling Capacity Calculation”

on pages 20 and 21 before selecting a model.

Handling

Warning

Thoroughly read the Operation Manual.

Read the Operation Manual completely before operation, and

keep this manual where it can be referred to as necessary.

Operating Environment/Storage Environment

Warning

1. Do not use in the following environment as it will

lead to a breakdown.

1) In locations where water vapor, salt water, and oil may

splash on the product

2) In locations where there are dust and particles

3) In locations where corrosive gases, organic solvents,

chemical fluids, or flammable gases are present (This

product is not explosion proof.)

4) In locations where the ambient temperature exceeds the

limits as mentioned below

During transportation/storage: –15

°

C to 50

°

C (But as long

as water or circulating fluid

are not left inside the pipings)

During operation (Air-cooled type): 2

°

C to 45

°

C

5) In locations where condensation may occur

6) In locations which receive direct sunlight or radiated heat

7) In locations where there is a heat source nearby and the

ventilation is poor

8) In locations where temperature substantially changes

9) In locations where strong magnetic noise occurs

(In locations where strong electric fields, strong magnetic

field

s, and surge voltage occur)

10) In locations where static electricity occurs, or conditions

which make the product discharge static electricity

11) In locations where high frequency occurs

12) In locations where damage is likely to occur due to lightning

13) In locations at altitude of 3000 m or higher (Except during

storage and transportation)

∗

For altitude of 1000 m or higher

Because of lower air density, the heat radiation ef

fi

ciencies

of the devices in the product will be lower in the location at

altitude of 1000 m or higher. Therefore, the maximum

ambient temperature to use and the cooling capacity will

lower according to the descriptions in the table below.

Select the thermo-chiller considering the descriptions.

Upper limit of ambient temperature: Use the product in ambient

temperature of the described value or lower at each altitude.

Cooling capacity coefficient: The product's cooling

capacity will lower to one that multiplied by the

described value at each altitude.

14) In locations where strong impacts or vibrations occur

15) In locations where a massive force strong enough to de-

form the product is applied or the weight from a heavy ob-

ject is applied

16)

In locations where there is not sufficient space

for maintenance

17) Insects or plants may enter the unit

2. The product is not designed for clean room usage. It

generates particles internally.

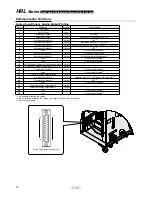

Altitude [m]

Upper limit of ambient temperature [

°

C]

Cooling capacity coefficient

Less than 1000 m

45

1.00

Less than 1500 m

42

0.85

Less than 2000 m

38

0.80

Less than 2500 m

35

0.75

Less than 3000 m

32

0.70

HRL

Series

Specific Product Precautions 1

22

Be sure to read this before handling the products. Refer to the back cover for safety instructions. For temperature control

equipment precautions, refer to the “Handling Precautions for SMC Products” and the “Operation Manual” on SMC website:

https://www.smcworld.com