Fuel System

13---14

Chattering sound properties

Testing with a hand powered pump does not create the same

circumstances as when the injector is fitted in the engine. Only

with new nozzles are the test results reliable. With used

nozzles, there is no chattering (creaking) sound when the

tester is pumped at a certain rate. This has to do with the de-

sign of the nozzles.

However, with a rapid pumping on the tester handle, it should

be possible to hear the chattering (creaking) sound or/and

see a mist of the fuel jetting out.

Tightness of nozzle

Press down the tester pump lever until the pressure rises to

approx. 20 bar below the adjusting value. Maintain this pres-

sure for approximately 10 seconds and check whether drops

of fuel are formed on the point of the nozzle. If the injector

leaks, it should be cleaned or the nozzle should be changed.

N. Reconditioning injectors

1. Secure the injector in a suitable way.

2. Unscrew the nozzle cap nut. Remove the nozzle and the

parts inside the holder.

3. Clean the nozzle in cleaning fluid both inside and outside.

4. Clean the nozzle holes with a needle (including in cleaning

set 8360 83288).

5. Test the movement of the nozzle valve as follows:

213--- 30

Rinse the parts thoroughly in fuel or testing fluid. Pull the valve

out of the nozzle body to 1/3 of its length. If the fit is correct,

the valve should be able to slide down in the nozzle body

under its own weight. Turn the valve slightly and repeat the

test. Should the nozzle valve bind slightly, it should be

changed.

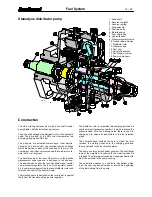

213--- 31

1

2

3

4

5

6

7

8

9

Injector

1. Fuel inlet

6. Nozzle body

2. Leak---off fuel

7. Pressure chamber

3. Shim

8. Nozzle valve

4. Pressure spring

9. Nozzle hole

5. Valve stop spacer

6. Before assembling, all parts should be carefully cleaned in

clean fuel or testing fluid.

7. Put the same thickness of shim back as were fitted earlier.

Note possible adjustment of the opening pressure. Assemble

the rest of the injector. Note the position of the spring guide

and the valve stop spacer.

8. Tighten the nozzle cap nut by hand and then to

60 Nm

.