Crankshaft

5---1

5. CRANKSHAFT

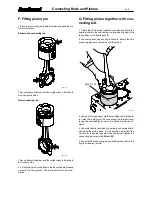

A. Removing crankshaft

1. Remove the oil sump.

2. Disconnect the balancing unit lubricating oil pipe from the

cylinder block and unscrew the balancing unit fixing bolts. Re-

move the balancing unit and the lubricating oil pipe (

only

420---engines

).

3. Unscrew the lubricating oil pump pressure pipe fixing

screws from the cylinder block. Remove the oil pump and the

suction and pressure pipes.

4. Remove the flywheel and the flywheel housing.

5. Detach the belt pulley/hub from the crankshaft front end

(see instr.

timing gears

).

6. Remove the connecting rod bearing caps and push the

connecting rods out of the way of the crankshaft.

7. Remove the main bearing caps and lift out the crankshaft.

B. Checking crankshaft

1. Clean the crankshaft. Do not forget the oilways.

25--- 1

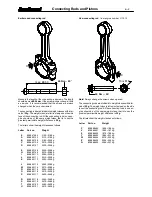

2. Measure the journal wear in several points. Out---of---round,

taper or other wear must not exceed

0,03 mm

.

3. Refit the bearing caps with new bearing shells and tighten

them to the correct torque. Measure the I.D. with a dial gauge

which has been zeroed to the dimensions obtained in point 2.

With this method the indicator shows the actual bearing clear-

ance. Measure in several points in case the worn bearing

housing is not round.

25--- 2

4. If the bearing clearance exceeds

0,18 mm

for main bear-

ings or

0,14 mm

for connecting rod big---end bearings with

new bearing shells, the bearing journals on the crankshaft

should be ground. Refer to the specifications for the relevant

correct undersize and the corresponding bearings, see

technical data, point

crankshaft

.

When grinding note that

the journal edges must remain round

.

Note!

If needed, also the main bearing can be fitted with outer

diameter 1,0 mm oversize and inner diameter 0,5 mm under-

size. Ordernumber is 8361 40950 (includes halfs 55593 and

55600). The main bearing housing is machined to

92,000...92,025 and crankshaft to 84,485...84,520.

C. Changing crankshaft gears

9052 48800

25--- 3

1. Apply puller for the crankshaft gears and pull off both gears.

2. Clean the seat on the crankshaft with, for example, a wire

brush.

3. Heat the new gears to

200

˚

C

. Tap them onto the shaft with

a suitable sleeve or soft drift. Note the position of the key and

ensure that the aligning marks on the front gear are visible.

Leave it to cool.