P68

Introduction

7.

縫製時的故障、原因和對策

7. Troubles and corrective measures

(sewing conditions)

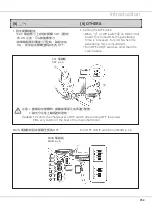

4. 線切不斷

4. Threads are not

trimmed.

(僅限底線)

(Bobbin thread only)

◎ 更換固定刀。

◎ 把固定刀再弄彎一些。

◎ 調整動刀位置。

◎ 調整針和旋梭的同步。

◎ 高底線張力。

◎ Replace the counter knife.

◎ Increase the bend of the counter knife.

◎ Correct the position of the moving knife.

◎ Correct the timing between the needle and the shuttle.

◎ In crease the bobbin thread tension.

44

40

44

40

① 固定刀不鋒利。

② 針孔導向器和固定刀高低差小。

③ 動刀位置不好。

④ 最終針跳線。

⑤ 底線張力低。

① The counter knife is dull.

② The difference in level between the needle

hole guide and the counter knife is not

enough.

③ The moving knife has been improperly

positioned.

④ The last stitch is skipped.

⑤ Bobbin thread tension is too low.

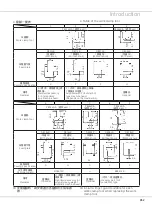

1. 始縫時脫線

1. The needle thread

slips off at the start

of bar-tacking.

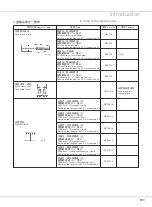

2. 常斷線

化纖線拉斷

2. Thread often breaks

or synthetic fiber

thread splits finely.

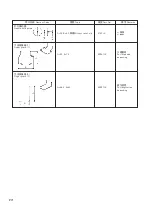

3. 常斷針

3. The needle often

breaks.

① 始縫時跳針。

② 切線後上線長度太短。

③ 底線過短。

④ 第 1 針的上線張力太高。

⑤ 夾線不穩定(布料容易伸長、線

不滑、線粗等)

⑥ 第 1 針的間距小。

① Stitches are slipped at the start.

② The needle thread remaining on the needle

after thread trimming is too short.

③ The bobbin thread is too short.

④ Needle thread tension at 1st stitch is too

high.

⑤ Thread clamp is unstable (material

is apt to be expanded, thread is hard to

slide, thread is thick, etc.).

⑥ Pitch at 1st stitch is too small.

◎ 機針和旋梭的間隙調整為 0.05 ∼ 0.1mm。

◎ 設定始縫時緩起動。

◎ 調節第 2 線張力器的浮線量。

◎ 把挑線彈簧弄強或把第一線張力盤的張

力減弱。

◎ 減弱底線張力。

◎ 弄大針孔導向器和固定刀的間隙。

◎ 降低第 1 針的張力。

◎ 降低縫製開始第 1 針的轉速。

(600 ∼ 1000sti/min 左右)

◎ 夾線針數增加 3 ∼ 4 針。

◎ 增長第 1 針的間距。

◎ 下降第 1 針的上線張力。

◎ Adjust the clearance between the needle and the

shuttle to 0.05 to 0.1 mm.

◎ Set soft-start sewing at the start of bartacking.

◎ Correct the thread tension release timing of

the thread tension controller No. 2.

◎ Increase the tension of the thread take-up spring, or

decrease the tension of the thread tension

controller No. 1.

◎ Decrease the tension of the bobbin thread.

◎ Increase the clearance between the needle hole guide

and the counter knife.

◎ Decrease the tension at 1st stitch.

◎ Decrease the number of rotation at 1st stitch at the

sewing start. (Extent of 600 to 1,000 sti/min)

◎ Increase the number of stitches of thread clamp

to 3 to 4 stitches.

◎ Make the pitch at 1st stitch longer.

◎ Decrease the needle thread tension at 1st stitch.

◎ 卸下用細磨時或銼刀磨平。

◎ 用銼刀磨,或換新。

◎ 調節布壓腳的位置。

◎ 卸下中旋梭,清除線頭。

◎ 減弱上線張力。

◎ 減弱挑線彈簧。

◎ 使用矽油。

◎ Take it out and remove the scratches using a fine

whetstone or buff.

◎ Buff or replace it.

◎ Correct the position of the work clamp foot.

◎ Take out the shuttle and remove the fibrous

dust from the shuttle race.

◎ Reduce the needle thread tension.

◎ Reduce the tension.

◎ Use silicone oil.

◎ 更換機針。

◎ 調節布壓腳。

◎ 根據縫製物選用適當的機針。

◎ 調整針和旋梭位置。

◎ 弄寬機針和挑線桿的距離。(23∼25mm)

◎ Replace the bent needle.

◎ Correct the position of the work clamp foot.

◎ Replace it with a thicker needle according to the

material.

◎ Correctly position the needle and the shuttle.

◎ Widen the distance between the needle and the wiper.

(23 to 25 mm)

42

49

17

16

44

42

49

17

16

44

44

16

17

15

44

16

17

15

14

43

40

45

14

43

40

45

① 旋梭、驅動器上有傷。

② 針孔導向器上有傷。

③ 機針碰布壓腳。

④ 線頭進入大旋梭的溝裡。

⑤ 上線張力過強。

⑥ 挑線彈簧過強。

⑦ 化纖線磨熱而斷。

① The shuttle or the driver has scratches.

② The needle hole guide has scratches.

③ The needle strikes the work clamp foot.

④ Fibrous dust is in the groove of the

shuttle race.

⑤ The needle thread tension is too high.

⑥ The tension of the thread take-up

spring is too high.

⑦ The synthetic fiber thread melts due

to heat generated on the needle.

① 針彎了。

② 針碰布壓腳。

③ 針過粗。

④ 驅動器把針弄得過彎。

⑤ 在縫製開始時壓腳壓住縫紉機線

(機針彎曲)。

① The needle is bent.

② The needle hits the work clamp foot.

③ The needle is too thin for the material.

④ The driver excessively bends the needle.

⑤ Needle thread is stepped on by the work

clamp foot at the start of sewing.

(Needle bend)

對策

Corrective measures

現象

Trouble

原因

Cause

頁

Page

Содержание LKS-1900AN

Страница 1: ...LKS 1900AN 使用說明書 INSTRUCTION BOOK ...

Страница 2: ......

Страница 57: ...P38 Introduction ...