17. MMA mode indicator .

18. 2T trigger indicator.

19. 4T trigger indicator.

20. Trigger control mode button.*

21. TIG parameter setting indicator.*

22. Parameter select/adjust Knob.*

23. MMA arc force setting Indicator.*

24. MMA welding current setting Indicator.

25. MMA hot start setting Indicator.*

26. Water cooling mode indicator

27. Air cooling mode indicator

28. Water /air cooling selection button.*

29. Alarm indicator.*

30. Water cooling system error indicator.*

31. Digital display value current indicator.

* Denotes more detailed explanation of function to

follow.

6.1.2. Further Controls Explained

LH Multifunction Display (9)

Before welding this displays the setting selected or

being adjusted using the control knob (22). During

welding it displays welding current. The parameter

setting displayed is indicated by the LEDs beside the

display; Current (A), Time (S), Percentage (%) and Fre-

quency (Hz). If left inactive for several seconds, dis-

play will revert back to main welding current setting.

TIG HF/ Lift Ignition Modes (15, 16)

For TIG welding process, contact of the torch tung-

sten to the workpiece will cause contamination of

the tungsten and the workpiece that will adversely

affect the weld quality, especially when the tungsten

is electrically energised.

HF Ignition (High Frequency) sends a pulse of high

energy electricity through the torch system that is

capable of ‘jumping’ between the tungsten and the

workpiece, ensuring arc starting without any contact

between the tungsten and workpiece. The disadvan-

tage of HF ignition is that the high energy electrical

pulse creates significant electrical and radio signal in-

terference, which limits its use around sensitive elec-

tronic equipment such as computers.

Lift TIG Ignition is a compromise that minimises

tungsten contamination while eliminating the elec-

trical interference of HF start systems. Lift arc start-

ing works by lightly resting the tungsten on the work

piece, activating the torch trigger signal and then

lifting the tungsten off. The control circuit will sense

when the tungsten is removed from the work piece

and send a low powered pulse of electricity through

the tungsten that will cause the TIG arc to initiate. Be-

cause the tungsten is not ‘live’ when it is in contact

with the work, contamination is minimised.

6. MACHINE USE

6.1. MACHINE LAYOUT DESCRIPTION

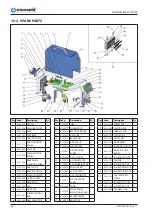

6.1.1. Layout for the front and rear panel

1. “--” Output terminal.

2. TIG torch gas connector.

3. TIG torch remote connection socket.*

4. “+” Output terminal.

5. Inlet gas connector.

6. Water cooler remote connection socket.

7. Input power cable.

8. Power switch

21

25

13

14

30

9

24 23

12

11 10

20

27

26

15

16

17

Spot

welding

29

Pulse

welding

on and

off

18

19

22

28

Control Panel

9. LH multifunction display.*

10. Digital display value frequency indicator.

11. Digital display value time indicator.

12. Digital display value percentage indicator.

13. RH voltage display.

14. Welding output mode button.

15. Hf TIG mode indicator.*

16. Lift TIG mode indicator.*

21

1.995.229 EN - Rev. 1.1

NOVATIG 403 DC PULSE