23

Lubrication and Maintenance

Never leave chemicals in the tank that may settle

to the bottom, harden and break into lumps as this

may block the suction filter.

Dispose of unused chemical, chemical mix, rinse

water and chemical containers as recommended

by the chemical manufacturer or the relevant

government authority.

Caution

Do not use a high pressure washer to

clean around fan bearings, pump seals or

electrical valves if fitted.

Tyres

Inspect the tyres regularly and inflate to 250 kpa

(36 psi) if necessary.

Diaphragm Pump

Drain the oil from the pump annually, or at the end

of each spraying season. Refill with SAE 20W-40

multi-grade engine oil.

Remove the pump heads, carefully inspect the

diaphragms and replace if necessary. Also check

the inlet and outlet valves, seats and springs for

wear, damage or chemical corrosion and replace

as necessary.

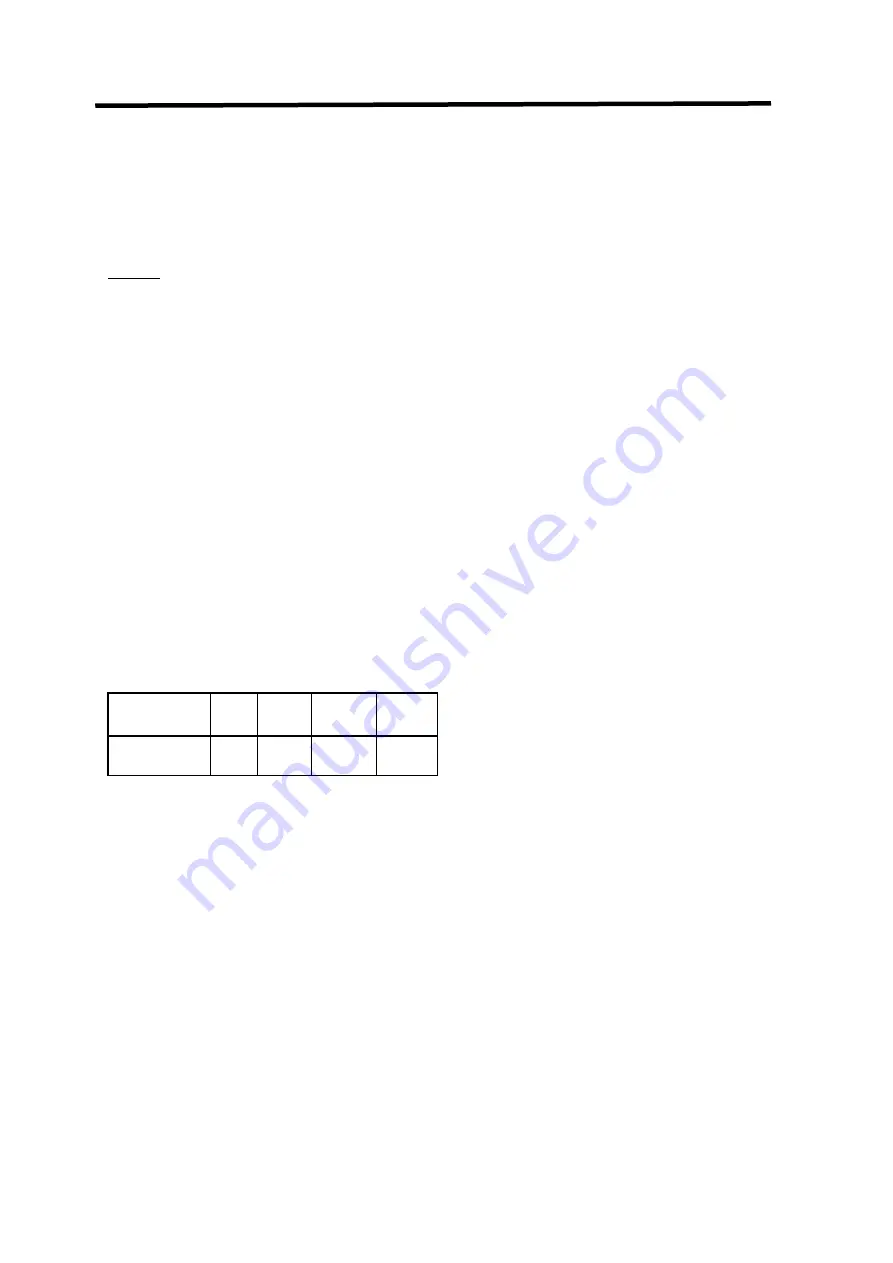

Check the air pressure in the surge chamber at

the side of the pump. The air pressure behind the

surge chamber’s diaphragm smoothes out the

pulsations in fluid flow and should be set in

accordance with the spraying pressure being

used, as shown in the chart below.

Spraying (Bar)

pressure (psi)

2 - 5

29 - 73

5 - 10

73 - 145

10 - 20

145 - 290

20 - 50

290 - 725

Surge air (Bar)

pressure (psi)

2

29

2 - 5

29 - 73

5

– 7

73 - 102

7

102

Adjust the pressure at the valve fitting on the

chamber using a compressed air hose fitted with

a tyre valve connection and a reliable pressure

gauge.

Refer to the pump instruction manual for further

details on the above maintenance operations.

Wheel Hubs

Remove the wheel hubs annually and check that

the bearings and seals are in good condition.

Repack the bearings with multi-purpose grease

as required.

Adjust the wheel bearings by tightening the axle

nut, then backing it off by approximately 1/6 turn

before installing the cotter pin. Check that the

hubs are free to rotate without any end play.

Annual Inspection (or 350 hours)

At the end of each season or every 350 hours

inspect the sprayer for any signs of damage,

corrosion or leakage.

Replace any parts that are affected by chemical

contamination.

Check that all bolts are securely tightened,

including the tank mounting bolts, axle U-bolts

and wheel nuts. Check that all hose connections

are tight.

Содержание Stiletto 2000L

Страница 1: ...Operator s Manual MANAB08 REV F 12 11 19 Air Assist Sprayer 2000L Supaflo 2000L Stiletto...

Страница 26: ...25 Notes...

Страница 27: ...26...