Operating manual

Twister II NA

Copyright Silca S.p.A. 2015

2

GENERAL INTRODUCTION

The TWISTER II NA key-cutting machine has been designed according to CE speci

fi

cations. From the design

stage risks for the operator have been eliminated in all areas: transport, key- cutting, regulation and maintenance.

Other risks have been eliminated by the use of protective devices for the operator.

The protective devices used are designed not to provoke further risks and, above all, they cannot be ignored

unless deliberately cut out. They do not hinder visibility of the work area.

A special adhesive label is attached to the machine warning the operator to use goggles during the cutting

operations, and this is strongly recommended in this manual.

The material used in the manufacture of this machine and the components employed during use of the machine

are not dangerous and their use complies with standards.

Use

The TWISTER II NA must be installed and used as speci

fi

ed by the manufacturer.

If the key-cutting machine is used differently or for purposes different from those described in this manual, the

customer will forego any rights he may have over the Company. Furthermore, unforeseen danger to the operator

or any third parties may arise from incorrect use of the machine.

Negligence in the use of the machine or failure on the part of the operator to observe the instructions given in this

manual are not covered by the guarantee and the manufacturer declines all responsibility in such cases.

IT IS OBLIGATORY to read the manual carefully before using the machine.

Further Risks

There are no further risks arising from the use of the machine.

Protection and safety precautions for the operator

The TWISTER II NA key-cutting machine is built entirely to CE standards. The operations for which it has been

designed are easily carried out at no risk to the operator.

The adoption of general safety precautions (wearing protective goggles) and observation of the instructions

provided by the manufacturer in this manual eliminate all human error, unless deliberate. The TWISTER II NA

key-cutting machine is designed with features which make it completely safe in all of its parts and operation.

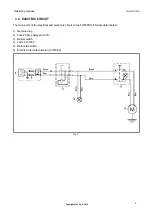

• Power supply

The key-cutting machine is powered by electricity supplied through a separate grounded plug.

• Start-up

The machine is turned on by means of the master switch located on the left-hand side. The switch has a safety

function that prevents untimely start-up when voltage returns after a power outage.

• Operation

The machine is started up by means of a motor switch.

• Illumination

The work area is illuminated by a lamp which operates when the machine is switched on with the master switch.

• Maintenance

The operations to regulate, service, repair and clean the machine have been devised in the simplest and safest

way possible. There is no danger of removable parts being re-placed wrongly or unsafely.

Содержание Twister II NA

Страница 1: ...Twister II NA Operating Manual Original Instructions D445453XA vers 1 0 EN...

Страница 4: ......