DELTA 2000 AY

Operating manual - English

14

Copyright Silca 1 998

7

MAINTENANCE

WARNING:

for repairs or replacement of parts for maintenance, the ‘CE’ mark is guaranteed only if original

spare parts provided by the manufacturer are used.

Although the DELTA 2000 AY key-cutting machine does not require special maintenance, it is advisable

to check and, if necessary, replace the parts subject to wear (cutting tool, brush, tracer point).

Replacement is simple and can be carried out by the operator.

CLEANING

: it is advisable to use a soft brush to keep the carriage and clamps free of chippings from

cutting operations.

WARNING:

DO NOT USE COMPRESSED AIR!

WARNING:

to keep the machine well maintained we recommend using protective oil, e.g. WD40 or similar,

applied to the burnished mechanical parts. This prevents oxidation of the parts in question

(clamps, guides, carriages, etc.).

Before starting any type of maintenance (checks or replacements), read the instructions below:

•

never carry out maintenance or servicing with the machine switched on.

•

always remove the mains plug.

•

follow all the instructions in the manual to the letter.

•

use original spare parts.

•

always check that any screws or nuts removed when replacing a piece are properly tightened.

7.1

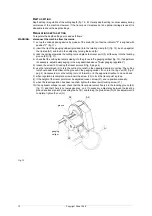

Cutting tool replacement

It is not necessary to remove the protective shield in order to replace the cutting tool (G).

WARNING:

unplug the machine from the mains.

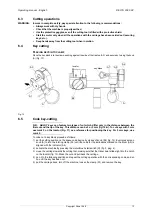

1) place the spanner provided in position on the motor shaft (fig. 14);

2) use a suitable spanner to loosen the new cutting tool locking nut.

WARNING:

the thread is left-handed.

3) replace the cutting tool after cleaning its seat;

4) install the new cutting tool and tighten the nut.

WARNING:

the tool rotates clockwise.

Fig. 14

7.2

Brush replacement

When the brush (J) is no longer effective it must be replaced, as follows:

WARNING:

unplug the machine from the mains.

1) place the spanner provided in position on the motor shaft (fig. 14);

2) use the wrench provided to loosen the brush locking screw (X) (fig. 15);

3) replace the brush and secure with the screw (X);

4) remove the spanner from the motor shaft.

Fig. 15

G

X

J

Содержание Delta 2000 AY

Страница 1: ...D413450XA vers 3 0 Operating manual EN...

Страница 4: ......