Operating manual - English

DELTA 2000 AY

Copyright Silca 1 998

5

3

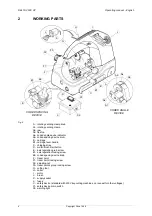

MACHINE DESCRIPTION

DELTA 2000 AY is a professional key-cutting machine for ABLOY keys. The machine comprises the fol-

lowing main parts:

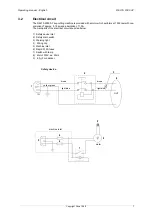

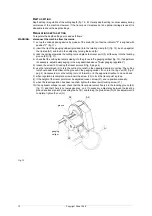

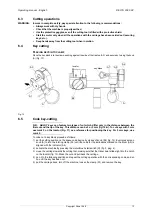

SAFETY DEVICE (X)

The device is conne cted to a power plug with a d ifferential switch. power the key- cutting machine by

pressing the switch (X1).

The warning light (X2) illuminates to indicate voltage in the plug (X3).

WARNING:

Switch (X1) is electromagnetic, in the event of a power failure it goes out automatically. When

electricity is restored it must be reset manually to power the machine again by means of the plug

(X3).

Fig. 6

MASTER SWITCH (D)

The motor and brush starting button is placed on the left side of the DELTA 2000 AY key-cutting machine.

WARNING:

the switch is constantly illuminated to indicate that the machine is live.

MOTOR

The DELTA 2000 AY has a direct drive motor (I). The transmission unit comprises the motor, cutter and

brush and is protected by a single cover (H).

MOBILE UNIT

The mobile unit comprises a carriage (B) which holds a code space setting device and a clamp for se-

curing the keys, with a code device for adjusting inclination (fig. 5, page 4).

The carriage (B) is fitted to the translation shaft and is moved manually by the operator.

It has been designed to avoid the accumulation of cutting dust or chippings.

The key-cutting machine has an inclined table which allows the chippings to collect in the special tray (C)

placed under the carriage and easily removable for thorough cleaning.

•

Brush (J)

The brush is used to eliminate burrs caused by the cutting process and is made of safe materials.

•

Cutting tool (G)

The cutting tool is the part of the

DELTA 2000 AY

machine which cuts the key blank. The tool is in HSS

super rapid steel and is protected by a special cover (H) to ensure safe operation.

•

Tracer point (F)

The tracer point is housed on the left-hand side of the machine base. Its depth settings are easily regu-

lated with the ring nut (F2).

•

Coded angle device

The device comprises:

- a clamp (A1) connected directly to the inclination setting device, which acts as a key

centring device and tip stop;

- a jaw (A2) with which to secure the key, activated by knob (A).

•

Coded spacing device

The code device comprises a knob (E2) to activate a graduated slide which determines the position of

the various cuts.

X

X1

X2

X3

Содержание Delta 2000 AY

Страница 1: ...D413450XA vers 3 0 Operating manual EN...

Страница 4: ......