.

4.

Lay the sheets flat. Scrape off the excess glue with a squeegee made from a balsa scrap. Finish glue cleanup with a damp

rag. Weight down the sheets on a flat surface and allow to dry thoroughly.

5.

Sand the wing skins smooth with the sanding block.

6.

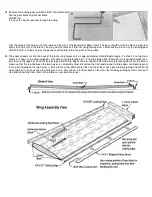

Cut one 7-sheet piece diagonally in two, with untaped side up, as shown by the dotted line marked "A" in the diagram

below.

Cut the other 7-piece diagonally in two, with the untaped side up, in the opposite direction as shown by the dotted line

marked "B". This provides 4 wing skins with the untaped, rougher glue seam on the outside surface of the wing. The

smoother, taped side should be used against the foam wing for best adhesion of the skin to the foam. The rougher, outer

glue seams can be sanded down partially with a sanding block before application of the skins and completed during final

sanding of the skin on the wing.

7.

Sand any irregularities or cutting wire marks from the cores with the large sanding block.

8.

Hold the cores together at the center joint. If there is any mismatch in the airfoil shape, sand as required to make them fit

smoothly together. Done this way, little matching will be required after planking.

THE SECRET OF A PERFECT FOAM WING

It's a simple matter of a FLAT table. Most tables are not flat, as can be seen by checking them with a good straightedge.

If a foam core is covered on a bowed or twisted surface, then the wing will be bowed or twisted. And a table that checks

out true but is flexible and will yield as you press on it will also spoil a wing. The ideal working surface is a sheet of plate

glass. Or, it is possible to find a thick piece of plywood that is perfectly true.

Like balsa blocks, foam blocks sometimes have built-in internal stresses and the core bows slightly when cut out of the

block. Skinning on a flat surface, in the sequence shown in the pictures, will correct minor bows.

Incidently, the washout in the Kougar wing is cut right into the foam core. The tip section is higher at the trailing edge

compared to the center section trailing edge. The washout will take care of itself. No blocking up or other steps are

required of the builder. Proceed with wing construction as if it were a standard wing.