.

77.

a. Cover the holes in the blind nuts

on the back of the firewall with

small pieces of tape to prevent

glue from oozing into the

threads. (Look ahead to Picture

No. 80.)

b. Epoxy the block and firewall to

the fuselage.

c. Shape and sand the block to the

contour formed by the firewall

and F-2.

Assemble the tank for use during Steps 78 and 79.

TIPS ON TANKS

IMPORTANT: To prevent fuel spray from staining the canopy, run the tank vent line

out of the bottom of the cowling. Fill the tank through the muffler pressure line or

needle valve line.

We occasionally receive suggestions from builders that a removable hatch be designed into the model for access to the gas

tank. Our opinion is this is not the best method in most cases. The hatch opening makes the nose weaker and there is no

good way to keep oil leaking in around the hatch. A method of fastening has to be built into the fuselage to hold a hatch in

place.

Modern plastic tanks are virtually indestructable under normal use and bursting or

cracking is almost unknown. If you use Sig Heat Proof Silicone tubing (which will

not harden or deteriorate in fuel) in the plastic tank, the tank will seldom have to be

removed. We have models in which tank has been installed for three or four years

without ever needing removal. So it is quite practical to put the tank in semi-

permanently. Check the models at a contest - you'll find that the majority have

sealed noses, as does this kit.

Read this before you drill the 7/8" hole in the firewall.

Some fliers prefer not to bring the tank cap through the firewall as is shown in the construction sequence in these instructions.

Instead they drill two holes for the vent tubes only and make the vent tubes long enough to extend through the firewall. This

method requires little sealing but it is more difficult to install and remove the tank. The best way to manage this is to feed long

pieces of fuel line through the holes and attach them to the tank in the cabin area. Steer the tank into the nose as the tubes

are pulled back through the holes. If you are undecided as to which method you should use, our advice is that large hole

installation shown in the construction pictures is the best for beginners.

Put scrap wood supports under and at the back of the tank. The front is supported by the 1/4" hole in the firewall. Seal the

tank cap in the hole with G.E. Silicone Bathtub Seal (available at hardware stores) or Devcon Seal-It. Put an oil-proof finish on

the firewall and in the hole before sealing the tank cap. Get some of the sealer on the sides of the hole and also put a bead

over the edge of the cap at the front. Should you need to remove the tank, break out the scrap wood supports in the rear and

push out the silicon rubber seal around the front cap. Reach into the fuselage and guide the tank outside.

Some builders, after putting their receiver battery in a plastic sack, taping it shut,

wrapping it in a foam rubber package and stuffing it into the nose under the tank,

then stuff paper toweling or foam rubber in to fill the nose compartment and keep

everything firmly in place.

After installation, put fuel tubing on the vent tube and run it to the outside of the

cowling on the bottom, so that fuel overflow is not blown over the wing-fuselage

joint, where it may leak into the fuselage. The best way to fill the tank is to take off

the fuel line to the needle vlave and pump the fuel in there until it runs out the vent.

Be sure and use a filter on your fuel supply can, and it is a good idea to have a filter

between the tank and the needle valve also.

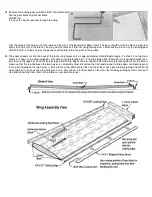

Pressure Feed

If the engine you are using is equipped with a muffler pressure tap, make use of it for a more even fuel feed and reliable

operation. The hookup for pressure feed is shown in the picture. To fill the tank, remove the fuel line from the engine and

pump the fuel in. When the tank is full, it will overflow through the muffler pressure line. Use transparent or translucent fuel

line so you can see the fuel starting to overflow when the tank is full. Should some fuel happen to get in the muffler, drain it

out before starting the engine. Do not try to fill the tank in reverse from the pressure line, the tank will not fill properly and fuel

may be forced into the engine.