ENTRANCE GATE INSTALLATION AND SETUP

4-3

SIG-QG-21-01

NOVEMBER 2021

Version: A

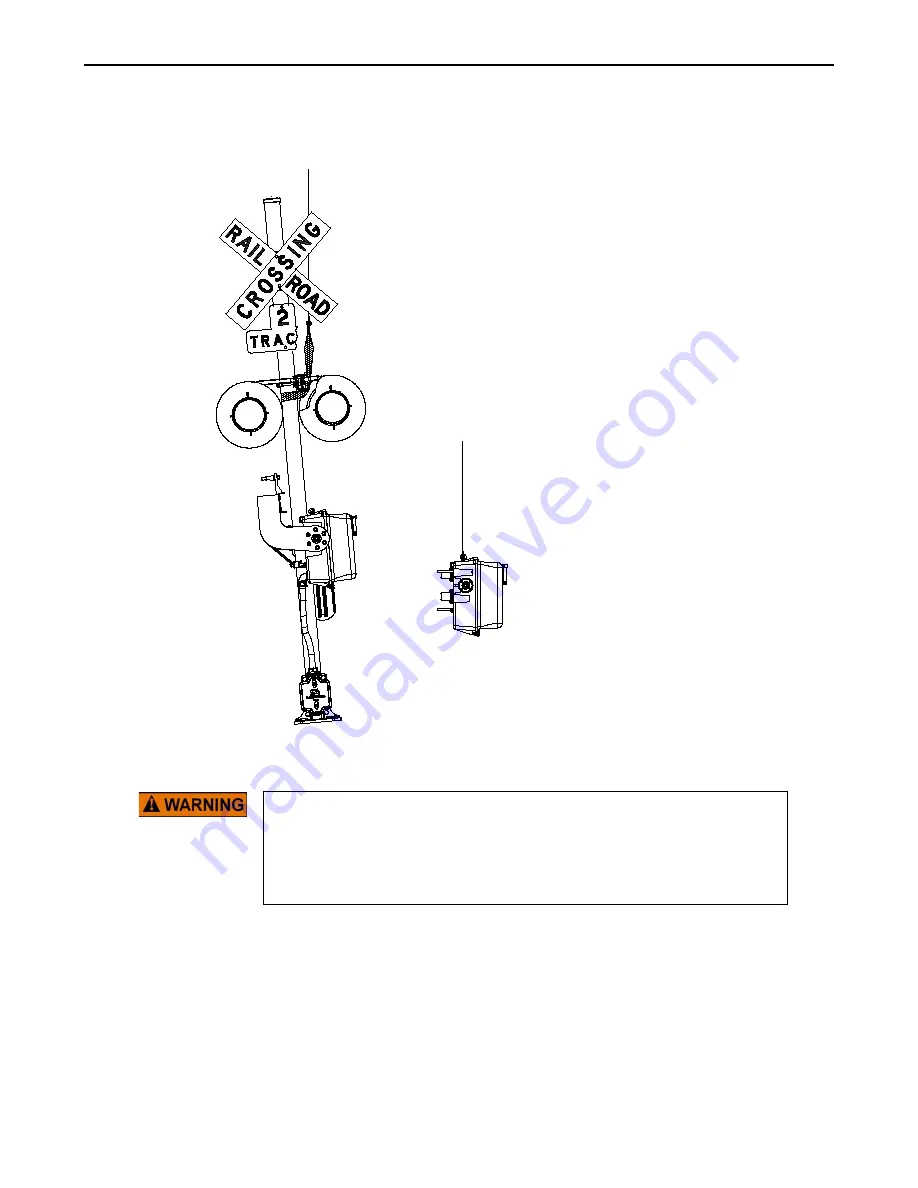

Figure 4-1

Lifting Gate Assembly Recommendation

WARNING

DO NOT LIFT COMPLETE GATE ASSEMBLY WITH LIFTING EYE

IN TOP OF MECHANISM HOUSING. DOING SO MAY RESULT IN

PERSONAL INJURY AND/OR DAMAGE TO THE MECHANISM.

3.

Clamp the mechanism in place.

Lift the mechanism and set it on top of the support clamp.

Secure the mechanism to the mast with the four, square head machine bolts, two saddles, nuts

and washers. Use a 1-1/8” wrench or socket to tighten the nuts to a torque range of

95 to 105 ft-lbs.

MECHANISM ONLY CAN BE

LIFTED INTO PLACE USING

THE LIFTING EYE PROVIDED

RECOMMENDATIONS FOR LIFTING

PRE-ASSEMBLED SIGNALS WITH

GATE MECHANISM.

1. SIGNAL ASSEMBLY MUST BE

WITHOUT ARM AND COUNTERWEIGHTS

2. LIFT POINT SHOULD BE A

MINIMUM OF 15" ABOVE GATE

MECHANISM.

3. LIFTING SLING CAN BE USED

AROUND MAST AND UNDER THE

JUNCTION BOX CROSSARM FOR

LIGHTS AS SHOWN

WEIGHT = 209 Lbs.

WEIGHT (AS SHOWN) = 560 Lbs.

Weight (as shown) = 461 lbs.

Weight = 110 lbs.

Recommendations for lifting pre-assembled

signals with gate mechanism:

1) Signal assembly must be without arm and

counterweights.

2) Lift point should be a minimum of 15” above gate

mechanism.

3) Lifting sling can be used around mast and under

the junction box crossarm for lights as shown.

Mechanism can only be

lifted into place using the

lifting eye provided.

Содержание SMART GATE S-80

Страница 44: ...PROGRAMMING 5 6 SIG QG 21 01 NOVEMBER 2021 Version A This Page Intentionally Left Blank ...

Страница 52: ...PROGRAMMING 7 6 SIG QG 21 01 NOVEMBER 2021 Version A This Page Intentionally Left Blank ...

Страница 54: ...HARDWARE TORQUE GUIDELINES 8 2 SIG QG 21 01 NOVEMBER 2021 Version A This Page Intentionally Left Blank ...