Note

Leakage

Besides continuous air consumption, a leakage can cause the positioner to try to compensate

the position deviation. This will result in premature wear in the entire control device.

• Check if there is leakage with "LEAKAGE TEST".

• If there is leakage, check the pneumatic connections for leaks.

Structure of pneumatic connection (Page 30)

Behavior in case of failure of the electrical auxiliary power and/or the supply pressure PZ

(Page 31)

5.4.1

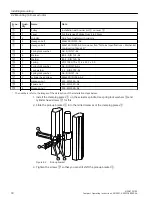

Structure of pneumatic connection

①

Output: Actuating pressure Y2 *)

②

Input: Supply pressure PZ

③

Output: Actuating pressure Y1

④

Exhaust air outlet with sound absorber, thread G¼

*) for double-acting actuators

Figure 5-2

Pneumatic connection, example

Connecting

5.4 Pneumatic connection

SIPART PS100

30

Compact Operating Instructions, 05/2021, A5E50188940-AA

Содержание SIPART PS100

Страница 14: ...Safety notes 3 2 Use in hazardous areas SIPART PS100 14 Compact Operating Instructions 05 2021 A5E50188940 AA ...

Страница 32: ...Connecting 5 4 Pneumatic connection SIPART PS100 32 Compact Operating Instructions 05 2021 A5E50188940 AA ...

Страница 42: ...Service and maintenance 8 5 Disposal SIPART PS100 42 Compact Operating Instructions 05 2021 A5E50188940 AA ...