05.91

6 NC Channel/PLC Interface (DB 10 ... DB 25)

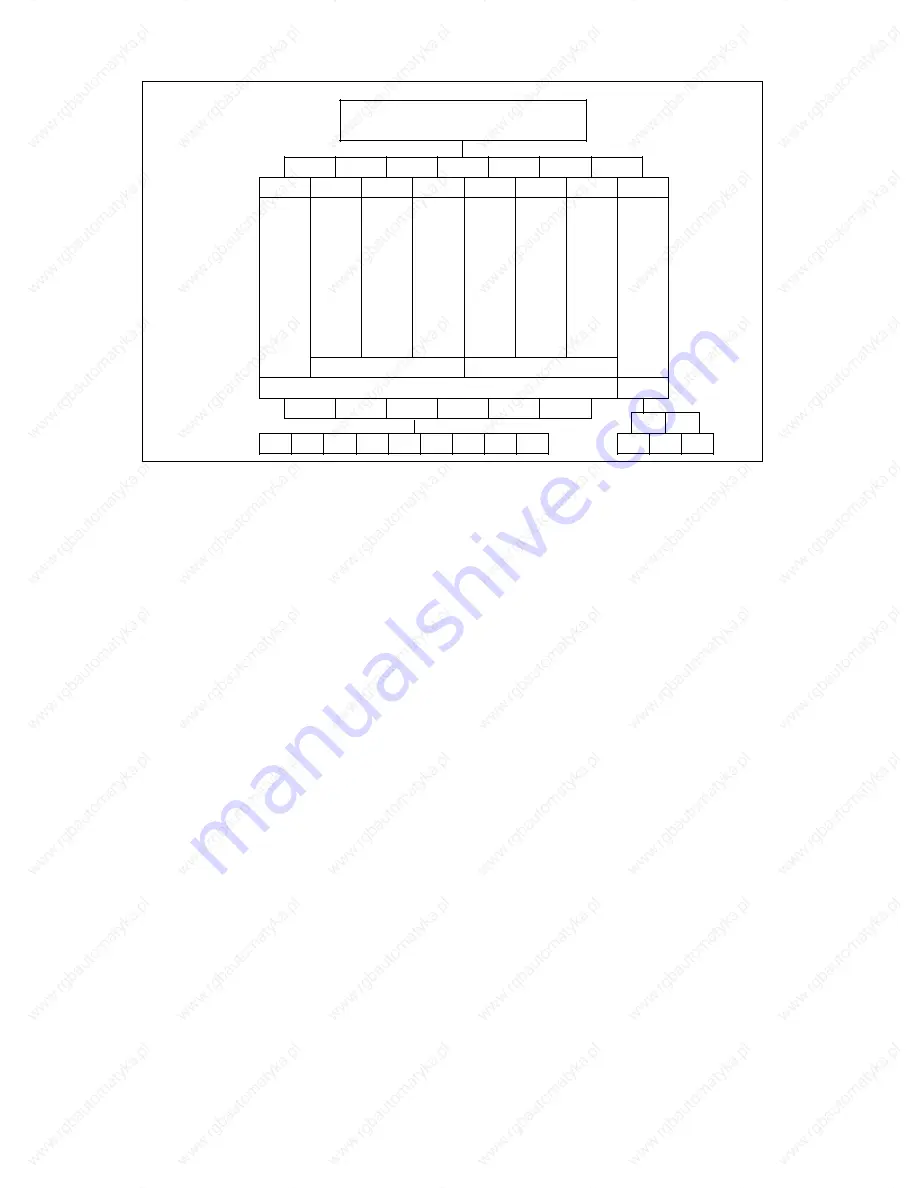

6.1 Introduction to channel structure

Channel structure: programmable allocation of channels

Mode

group

>

Axes/

spindles

Central

part program memory

1

2

3

4

5

6

7

8

X1

Z1

S1

C

S2

Turn-

ing and

milling

T1

Turret

1

X2

Z2

(S1)

T2

Turret

2

Q1

Q2

Q3

Loader

Slide 1

Slide 2

1

2

X1

Z1

S1

C

S2

T1

X2

Z2

T2

X2

Z2

T2

Channel

In addition to the processing channels in which the programs controlling the machine units run,

additional channels can be allocated special tasks. In this case, channels 3 and 6 control the

execution of save programs that can be run by the user after a tool breakage, enabling him to

retract and change the tool as well as restart the program. The spare channel 1 is intended for

a future coordination program able to control the entire procedure. This program will not

necessarily be dedicated to channel 1.

Depending on the workpiece being manufactured, machining programs have to be compiled for

reading in the central part program memory.

6.2

Mode groups

The channels are linked in higher-level mode groups. A single mode group contains the chan-

nels that always have to work simultaneously in the same mode for operational reasons. A

maximum of eight mode groups are permitted.

Within the mode group, each axis can be programmed in each channel. In the above example,

the loader has been allocated its own mode group. This permits operation of the loader

setting-up mode during workpiece production.

The assignment of:

•

NC CPU

NC channels

•

Servo CPU

Measuring circuit addresses

•

NC channels

Mode groups

•

NC axes

Mode groups

•

Spindles

Mode

groups

is effected by way of NC machine data.

©

Siemens AG 1991 All Rights Reserved 6ZB5 410-0HE02

6

–

3

SINUMERIK 880 (PJ)