International English

3 Commissioning

MICROMASTER 440 Operating instructions

6SE6400-5CA00-0BP0

43

Note

P0308 & P0309 are only visible if P0003

≥

2. Only one of the parameters is

shown depending on the settings of P0100.

P0307 indicates kW or HP depending upon the setting of P0100. For detailed

information, please see the Parameter List.

Changing motor parameters is not possible unless P0010=1.

Ensure that the inverter is configured correctly to the motor, i.e. in the above

example delta terminal connection is for 230 V.

External motor thermal overload protection

When operated below rated speed, the cooling effect of fans fitted to the motor

shaft is reduced. Consequentially, most motors require de-rating for continuous

operation at low frequencies. To ensure that the motors are protected against

overheating under these conditions, a PTC temperature sensor must be fitted to

the motor and connected to the inverter control terminals and P0601 enabled.

3.2.4.3

Commissioning with the Advanced Operator Panel (AOP)

The Advanced Operator Panel (AOP) is available as an

option. Its advanced features include the following:

Multilingual clear text display

Upload/download of multiple parameter sets

Multidrop capability to drive up to 30 inverters

Please refer to the AOP Manual for details or contact your

local Siemens sales office for assistance.

3.3 General

operation

For a full description of standard and extended parameters, please refer to the

Parameter List.

Notes

1. The inverter does not have a main power switch and is live when the mains

supply is connected. It waits, with the output disabled, until the RUN button is

pressed or for the presence of a digital ON signal at terminal 5 (rotate right).

2. If a BOP or an AOP is fitted and the output frequency is selected to be

displayed (P0005 = 21) the corresponding setpoint is displayed approximately

every 1.0 seconds while the inverter is stopped.

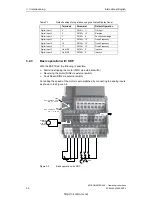

3. The inverter is programmed at the factory for standard applications on

Siemens four-pole standard motors that have the same power rating as the

inverters. When using other motors it is necessary to enter the specifications

from the motor's rating plate. See Figure 3-7 for details on how to read motor

data.

4. Changing motor parameters is not possible unless P0010 = 1.

5. You must set P0010 back to 0 in order to initiate a run.

http://nicontrols.com

Содержание MICROMASTER 440 Series

Страница 1: ...MICROMASTER 440 Operating instructions Issue A1 User Documentation http nicontrols com ...

Страница 113: ...Index International English MICROMASTER 440 Operating instructions 112 6SE6400 5CA00 0BP0 http nicontrols com ...

Страница 115: ...MICROMASTER 440 Operating instructions 114 6SE6400 5CA00 0BP0 http nicontrols com ...