C D F 6 0 0 - 2 2 0 0 | S I C K

8015922/1CC9/2021-07-12 • Subject to change without notice •

SICK AG

•

Waldkirch

•

Germany

•

www.sick.com

2

•

The device must only be mounted by inserting two screws

into the elongated drill holes.

•

Stable mounting equipment with sufficient load-bearing ca

-

pacity and appropriate dimensions for the fieldbus module.

The module has been optimized for mounting on standard

frame profiles. Weight 360 g (without cables).

Dimension drawing

•

Required switching space across the electrical connections:

approx. 300 mm, access to USB interface and rotary encod

-

ing switch: approx. 400 mm.

•

Clear view of the transparent panels on the rotary encod

-

ing switch and the optical indicators.

•

In order to achieve electromagnetic-compatible mounting,

a continuous metallic connection must be established with

the housing.

1.

Use the two elongated drill holes to mount the fieldbus

module in the lugs of the cover or the bar on the side. Ide

-

ally, the fieldbus module should be mounted in a horizontal

or vertical position, so that the writing on the rotary encod

-

ing switches reads correctly when viewed by the user.

2.

Mount the ID sensor and align it with the codes/transpon

-

ders to be identified as indicated in the corresponding

operating instructions. The

&

operating instructions of

the relevant ID sensor are available on the corresponding

product site online, e.g., for the CLV62x bar code scanner

at

www.sick.com/CLV62x.

Step 2: Electrical installation

•

Only skilled electricians with appropriate training

and qualifications are permitted to perform electrical

installation

.

•

Standard safety requirements must be met when working

in electrical systems!

•

Electrical connections between the fieldbus module and

other devices may only be made or separated when there

is no power to the system. Otherwise, the devices may be

damaged.

•

Where connecting cables with one end open are con

-

cerned, make sure that bare wire ends are not touching

(risk of short circuit when the supply voltage is switched

on). Wires must be appropriately insulated from each

other.

•

Wire cross sections of the supply cable from the cus

-

tomer's power system for the fieldbus module should be

designed and protected in accordance with the applicable

standards. Insert a separate, external fuse (max. 3 A slow-

blow) at the start of the supply cable to protect the fieldbus

module (and the ID sensor connected to it).

•

All electric circuits to be connected to the fieldbus module

must be designed as SELV circuits (SELV =

S

afety

E

xtra

L

ow

V

oltage).

a

DANGER

Risk of injury and damage caused by electrical current!

The CDF600-2200 fieldbus module is designed for opera

-

tion in a system with proficient grounding of all connected

devices and mounting surfaces to the same ground potential.

Incorrect grounding of the fieldbus module can result in

equipotential bonding currents between the fieldbus module

and other grounded devices in the system. This can lead to

hazardous voltages being applied to metal housing, cause

devices to malfunction or sustain irreparable damage and

damage the cable shield as a result of heat rise, causing

cables to set alight.

•

Only skilled electricians should be permitted to carry out

work on the electrical system.

•

Ensure that the ground potential is the same at all ground

-

ing points.

•

If the cable insulation is damaged, disconnect the power

supply immediately and have the damage repaired.

See

&

CDF600-22xx Fieldbus Module Technical Informa-

tion

(no. 8015924), available on the product site on the web

(

www.sick.com/CDF600-2)

for suggested courses of action

for eliminating hazards.

1.

In order to install the desired application, wire the fieldbus

module as appropriate for the ID sensor type with the help

of the optional pre-assembled SICK cables as shown in

the block diagram. The cables are only included as ac

-

cessories in the delivery of the module if they are ordered

separately. The part number varies by type for the required

M12 adapter cable to D-Sub HD ("DEVICE" connection)

for the ID sensor with Ethernet interface. It should, for ex

-

ample, be taken from the operating instructions or product

information for the ID sensor on the corresponding online

product page.

Cable types and lengths:

•

The cable used for the incoming supply cable must be

a screened cable, length of cable < 30 m.

Take appropriate measures to isolate unused open wire

ends (CAN bus) for the "POWER" connection (risk of

short-circuit)

•

Screened connection cable between fieldbus module

and ID sensor < 5 m, as a RS-232 interface to the data

transmission is used between fieldbus module and

ID sensor.

2.

Prepare and protect the supply voltage for the fieldbus

module. The level of the supply voltage for the unit consist

-

ing of fieldbus module and ID sensor is dependent on the

connected sensor, see

The fieldbus module provides a supply voltage range of

DC 10 V to 30 V. The supply voltage is also applied to the

connected ID sensor. The power supply and all connected

signals must comply with the regulations for extra-low volt

-

ages with safe separation (SELV) according to EN 61010.

10 V ... 30 V DC

3)

(LPS/SELV)

Cable e. g. no. 6048241, 2 m

(2 x 4-pin M12 plug, D-coded)

Cable e. g. no. 6048241, 2 m

(2 x 4-pin M12 plug, D-coded)

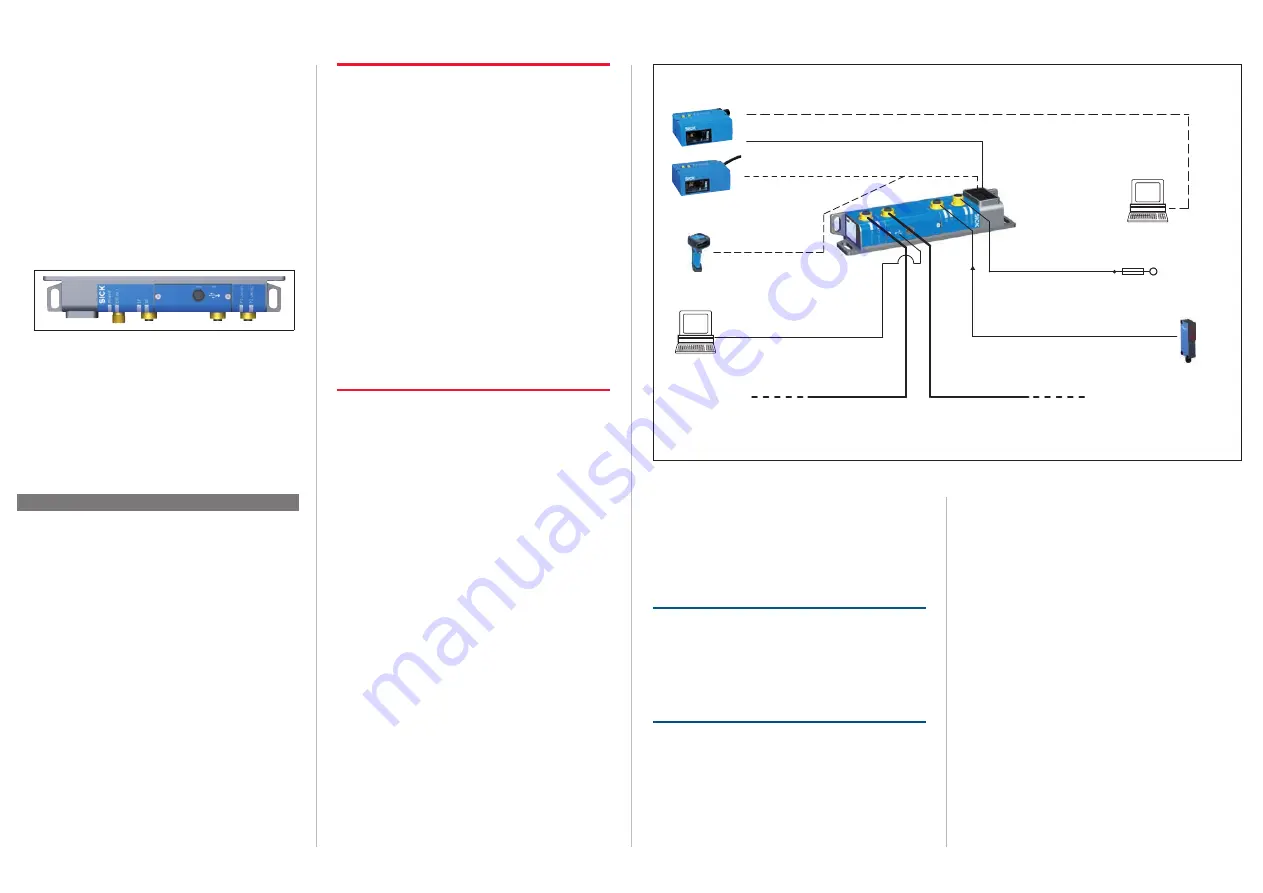

SOPAS ET

Trigger IN (reading clock)

e. g. CLV63x bar code scanner

(Ethernet version, M12)

Trigger

sensor

Data (Aux, RS-232)

Supply voltage

Data (Aux, RS-232)

Supply voltage

PROFINET (data)

PROFINET (data)

Supply voltage/

(CAN

2)

, if required)

Cable e. g. no. 6036384, 5 m

(5-pin M12 socket, A-coded/

open end)

Cable e. g. no. 6026133, 2 m

(5-pin M12 plug, A-coded/open end)

Ethernet (cable e. g. no. 6034414, 2 m,

4-pin M12 plug, D-coded/8-pin RJ45 plug)

Alternative connection of ID sensor

(Ethernet version) for configuration/

diagnostics

ID sensor

(Standard version,

with cable)

– or –

– or –

“USB”

“POWER

”

“EXT. IN 1”

SOPAS ET

1) Characteristic of the sensor related cable end depends of ID sensor type

2) CAN network always terminated at one end with resistor in the fieldbus module

3) Depends on connected ID sensor type

Data (RS-232)

Supply voltage

IDM16x

Configuration/diagnostics of

proxy compatible ID sensors

Cable no. 2057709, 0.3 m +

cable e. g. no. 6041540, 1.8 m

External

fuse

“DEVICE”

CDF600-2200

Fieldbus module

Cable

1)

e. g. no. 2041834, 2 m

(12-pin M12 plug, A-coded/15-pin D-Sub HD plug)

USB cable e. g. no. 6036106, 2 m

(4-pin plug type A/5-pin plug type

micro B)

„P2 PROFINET

“

„P1 PROFINET

“

Block diagram: CDF600-2200 fieldbus module connected to CLV6xx bar code scanner or IDM 16x hand-held scanner (example)

Power output of the power source:

The fieldbus module itself consumes < 5 W power (without

ID sensor and trigger sensor).

The additional power consumed by the connected ID sensor

and trigger sensor (if there is one) varies by type.

The output of the power supply unit must be dimensioned

based on the total consumption of all loads.

NOTE

Risk of damage caused by electrical current!

The supply voltage at the DEVICE connection is not short-

circuit-protected. If the "POWER" LED no longer lights up

following a short-circuit between pin 1 and pin 5, the device

must be sent to SICK Service so that its functionality can be

re-established.

3.

Do

not

connect the supply voltage yet.