Check the efficiency of the earthing connection of the socket (essential for the correct operation of the machine as well as for safety purposes).

-

the earth cable is correctly connected inside the electric system and on the internal machine parts.

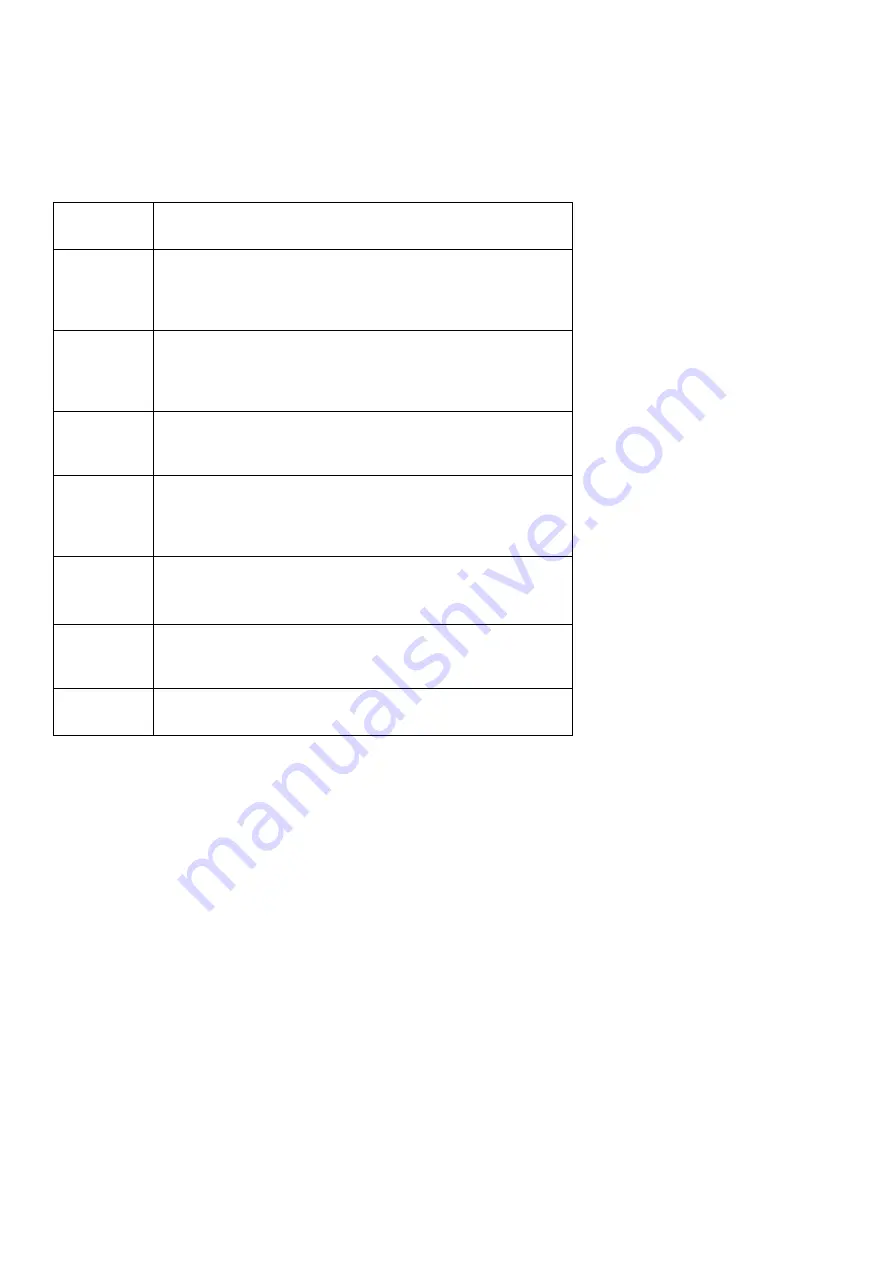

3. SOFTWARE CONFIGURATION SUMMARY TABLE

ENCODER

NOTCH

HIDDEN FUNCTIONS

0

Function for electronically resetting the shaft assembly using a

medium/large wheel.

Procedure described in the service manual, “

RESETTING THE SHAFT

ASSEMBLY

” paragraph

50

Function for enabling/disabling wheel spin with the “Str on/off ” button

for versions without a wheel protective casing.

Procedure described in the service manual paragraph “

MACHINE SOFTWARE

CONFIGURATIONS

”.

55

Neutral Logo or Logo1 or 2 setting

Procedure described in the service manual paragraph “

MACHINE SOFTWARE

CONFIGURATIONS

”.

131

Jap/USA/EUr market

To change the threshold to gx5

Procedure described in the service manual paragraph “

MACHINE SOFTWARE

CONFIGURATIONS

”.

169

Changing the video ratio 4:3, 16:9, 16:10

Procedure described in the service manual, “

MACHINE SOFTWARE

CONFIGURATIONS

” paragraph

200

Function for calibrating the automatic inner sensor.

Procedure described in the service manual paragraph “

INNER SENSOR

CALIBRATION

“.

244

Function for enabling wheel spin simulation. Procedure described in the

service manual paragraph “

MACHINE SOFTWARE CONFIGURATIONS

”.

4. SERVICE PROGRAMMES

The aim of these programmes is to make some data available, to allow the quick and easy checking of the efficiency of the various parts of the

machine.

The data are visualised in the service environment, which is accessed by first selecting the icon

.

“Utilities”, then the icon

“Configuration programmes”, then the icon

“Service program”.

After making the selection, the display will visualise an image showing (from the top):

- the geometric data of the wheel: width, diameter, distance;

- the unbalance values (without thresholds) relating to the last spin made;

- the angular positions (written in white and expressed in notches) of the unbalances relating to the last spin made;

- The software versions installed on the MBU32F board for the CPU (MBU) section of the graphic section (MSK).

- the presence of the threshold of 1 gram for the unbalance values shown. During normal working, when the “gr x 1” unbalance visualisation

mode is selected, the first gram of unbalance is not shown. In this condition, the message “1 OFF” is highlighted in the appropriate window. If,

on the other hand, you wish to visualise the first gram of unbalance as well, you must select the icon.

In this condition, the message “1 ON” is highlighted in the appropriate window.

In this condition, the sensitivity of the machine is also intensified so as to calculate and visualise the unbalance values with the greatest

precision possible.

This characteristic allows you:

to visualise the unbalance values with the maximum precision allowed, so you can balance a wheel perfectly and then carry out further checks

on it.

The technical assistance staff must always work with this condition.

- the presence of the rounding-off (to one inch) of the values obtained with the automatic sensor. When the rounding-off is activated, the

message “ON” is shown in the appropriate window. If you wish to visualise the diameters acquired with the precision of a tenth of an inch, it is

necessary to select the icon. The message “OFF” appears on the display, indicating the setting of this new condition.

Содержание S 64E

Страница 43: ...Fig 20 fig 21...

Страница 45: ......

Страница 46: ...SECOND VERSION OF PNEUMATIC SYSTEM from April 2016...

Страница 47: ...THIRD VERSION OF PNEUMATIC SYSTEM from March 2017...

Страница 48: ...FOURTH VERSION OF PNEUMATIC SYSTEM...

Страница 50: ...PEAL 32F...

Страница 51: ......

Страница 52: ...MBUGRF 2 LIGHT...

Страница 53: ......

Страница 54: ...COMIM Cod 4 119446B_EN 05 2018...