Operation Instructions for ZLP250

Temporarily Installed Suspended Access Equipment

17

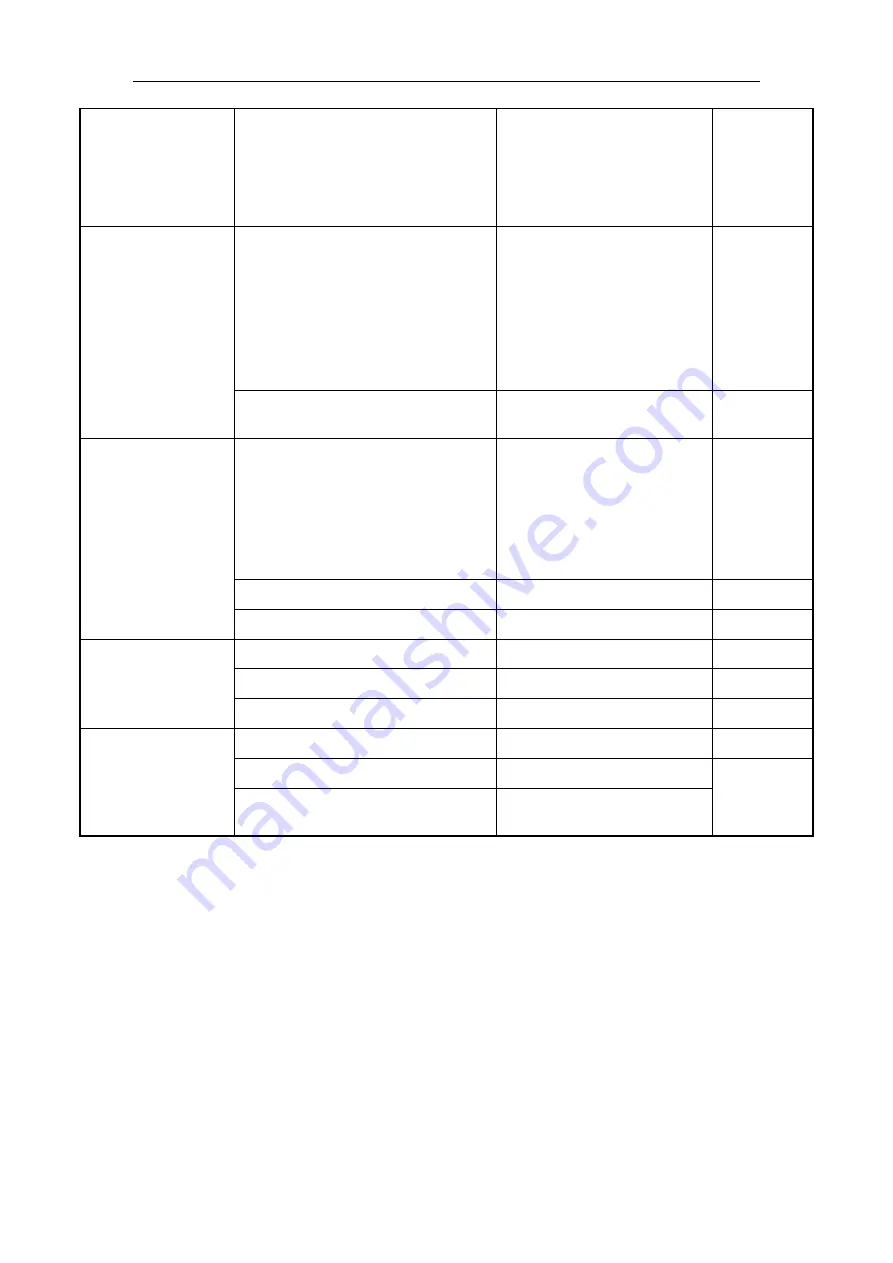

The steel rope is blocked in the hoist.

Fix the platform and examine

& repair hoist.

It

is

not

allowed

to

restart

the

platform

forcedly

Suspended platform

tilt

1. Sensitivity difference in motor

brake.

2. Difference in motor rotating speed,

and hoist rope pulling.

1. Adjust the spacing of motor

brake.

2. Check the rope pressing

device of hoist or replace rope

pressing device or replace

motor with incorrect rotating

speed.

Uneven in the load of suspended

platform.

Adjust the load of suspended

platform.

Hoist

cannot

actuate

suspended

platform

The electromagnetic brake is not

actuated:

1.

Rectifier damaged.

2.

No input voltage.

1.

Replace the rectifier.

2.

Check and adjust.

Input

voltage:

AC380

V

and

output

voltage:

DC99 V

Low voltage of the power supply.

Check and adjust the voltage.

Damage of hoist.

Check and repair the hoist.

Abnormal noise of

the motor or the

motor is hot

Operation lacking phases.

Check the power supply.

Lower or higher voltage.

Adjust the voltage.

Bearing damaged.

Replace.

Safety lock slip or

locking angle is too

big

Oil dust on the safety steel rope

Clean or replace the steel rope.

Problem wit rope clip.

Replace the clip.

Replace by

manufactory

Sluggish motion in safety lock.

Replace torsion spring of

safety lock.

7.

Maintenance

The daily maintenance and check, before operation of the equipment, will be

done by the operators and check periodically by the qualified personnel. The

maintenance and the check should be recorded.

7.1 Daily Maintenance

7.1.1

Safety lock

a.

Cleaning the surface;

b.

Cleaning the surface of the steel rope and clear out the rust;

c.

Prevent the water and dirty matter from entering the lock.

7.1.2

Hoist