Operation Instructions for ZLP250

Temporarily Installed Suspended Access Equipment

9

4.5.2

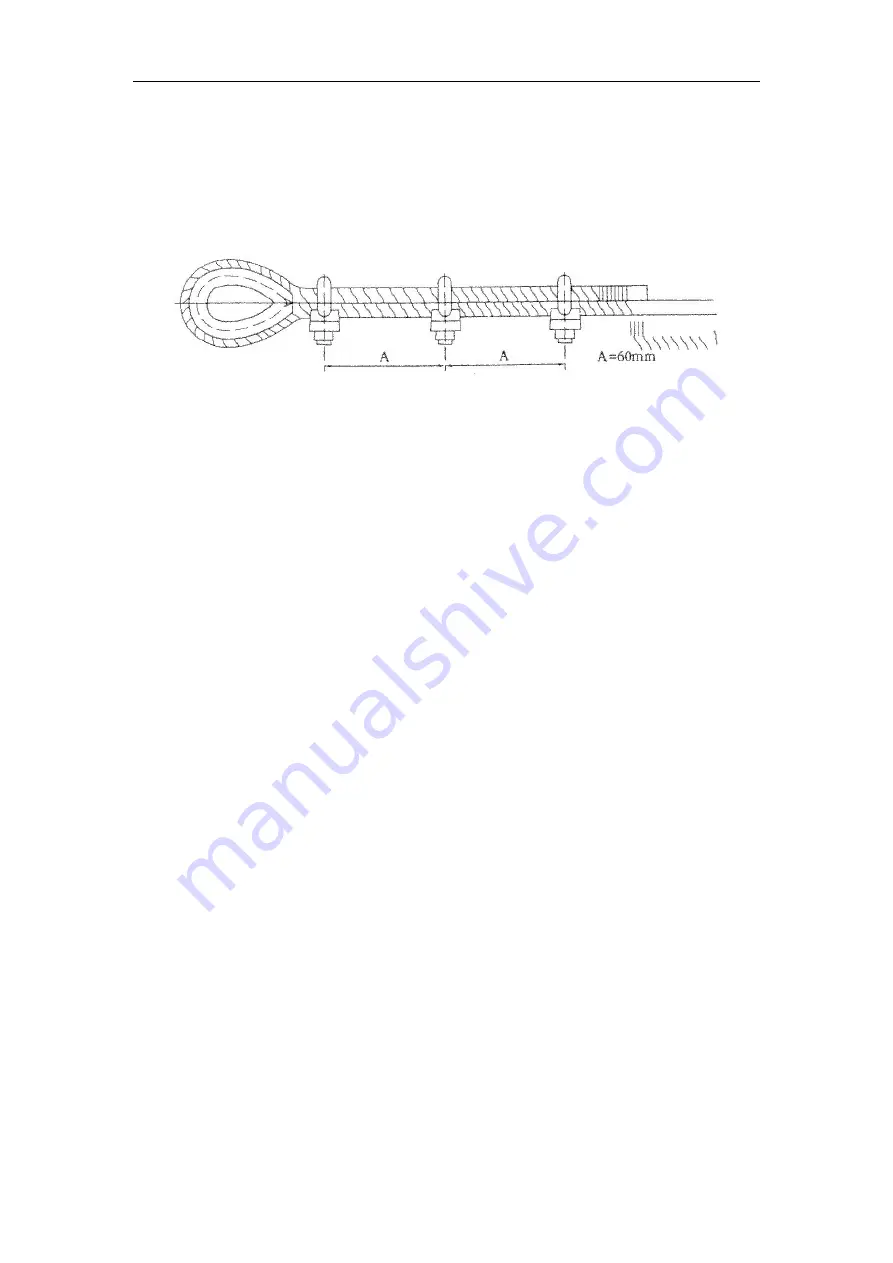

The fixing method at the end of steel rope should be in accordance with the

requirements of the standard GB5976-86 (see figure 7 as below). U bolt is fixed on

the rear portion of steel ropes; clamp is fixed on the working section of steel ropes,

which cannot be mixed up. The steel rope clamp cannot be alternately arranged on the

steel rope, and the correct clamping method is as follows:

Figure 7: The Correct Clamping Method

a.

Quantity of the clamps: 3 pieces (at least);

b.

Arrangement of the clamps (see figure 9 above);

c.

The distance between the clamps is 60 mm;

d.

Tightening of the clamp: the first clamp should be close to the rope ring and

tightened. Care must be taken that it is not allowed to damage the steel rope when

tightening, and then make the second and third clamps. It is necessary to make the

clamps tightened again after the steel rope is loaded one or two times.

4.5.3

Care must be taken that the steel ropes must not be damaged, deformed or

twisted.

4.7.4

The hoist must be fixed with the pins and bolts.

4.7.5

Make sure that the plugs of the motors and the control button be inserted into the

sockets of the control box correctly.

4.7.6

The power supply, connected with the control box, should have the null and

earth lines and the control box should be ground contacted reliably.

4.7.7

Make sure that the connection of the steel rope with the hoist is in normal,

otherwise, stop connection for check.

4.7.8

The remaining steel rope should be placed in order and bounded well.

4.7.9

The four heavy hammers must be hung onto the lower ends of the safety steel

rope respectively.

5.

Operation

5.1 Checking and Adjusting after Installation

5.1.1

Check if the connections are correct, the steel ropes are not damaged, the

clamping are correct, the nuts are tightened, the front beam overhang is in accordance

with the standard. Make sure that the moment of force of the stability of the

suspension mechanism is over two times of the overturning moment.

5.1.2

Check if the wiring is correct. The voltage of power should be within the range

of 380V

5%. After the power is connected, push the testing button on the power

leakage breaker, and power leakage breaker should work swiftly. Close the door of