Operation Instructions for ZLP250

Temporarily Installed Suspended Access Equipment

10

electric control box, and inspect if handle switch, universal switch and motor is

normal.

5.1.3

Checking electromagnetic brake:

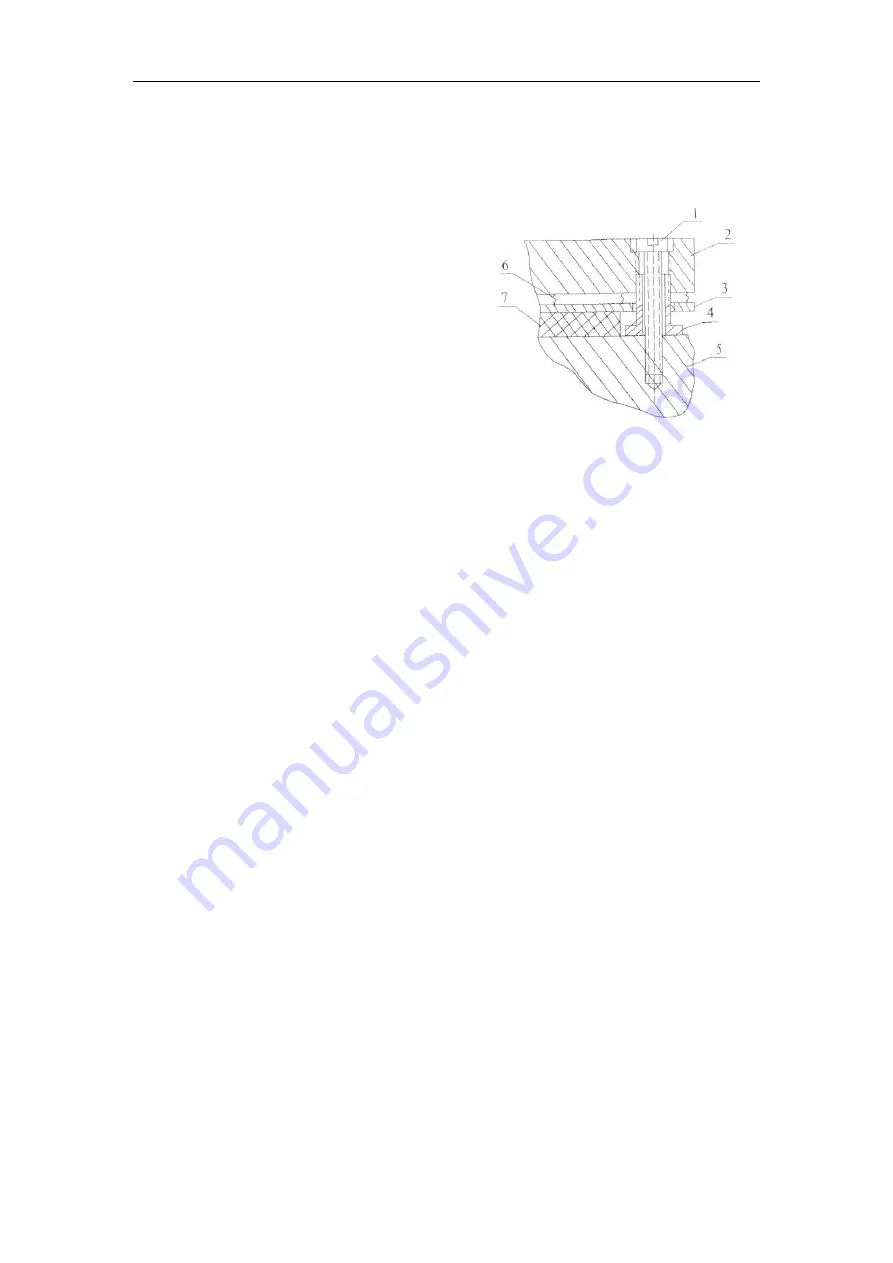

a. The spacing between the armature

and the electromagnetic disk should

be within 0.8-1.0 mm (see figure 10).

First, loose inner hexagon screw (1),

then adjust

the spacing by turning

hollow screw (4).

Finally, tighten

inner hexagon screw (1).

b. Power on to check the operation

of electromagnetic armature, the

armature must separate

with

friction

disc

completely

after

being

absorbed,

and no clog after power is off. The

armature

should press the

spring

disc completely under the

force of

spring.

Figure 8: Electromagnetic Brake

1.Inner hexagon screw 2. Electromagnetic disk

3. Armature 4. Hollow screw 5. Motor cover

6.Spring 7. Friction disk

5.1.4

Checking

safety lock: move the suspended platform upward about 1-2 m and

make its one end inclined about 3

°~

8

°

, the safety lock should be actuated to lock

the safety steel rope.

5.1.5

Make the suspended platform upward and downward 3-5 times for about 3-5 m

travel and check:

a.

The noise of the hoist should be normal and the electromagnetic brake will be

actuated reliably.

b.

Press emergency stop button or pull the limit switch, the suspended platform will

stop moving immediately.

c.

Make the suspended platform horizontal, if necessary.

5.1.6

Checking manually descending: move the suspended platform upward for about

3-5 m and stop it. Pull the manual descending device, the suspended platform can

move downward smoothly.

5.1.7

Adjustment of the upper limit stopper: move the suspended platform upward to

the highest position. Fix the limit stopper and adjust the location of the limit switch

and make sure that the limit switch will be actuated normally.

5.1.8

Rated load testing: The rated load should be evenly distributed on the working

platform. In the operating process no abnormal sound, and when stopping no sliding

movement. The safety lock should lock the safety steel rope flexibly and reliably

when the platform is in tilting.

5.2 Operation Procedure

5.2.1

Turn on the power supply.

5.2.2

Press the starting button.

5.2.3

After the work completed, cut off the power supply and make sure the control

box is locked.