ENGLISH

EN-2

1/2"

3/8"

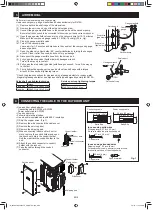

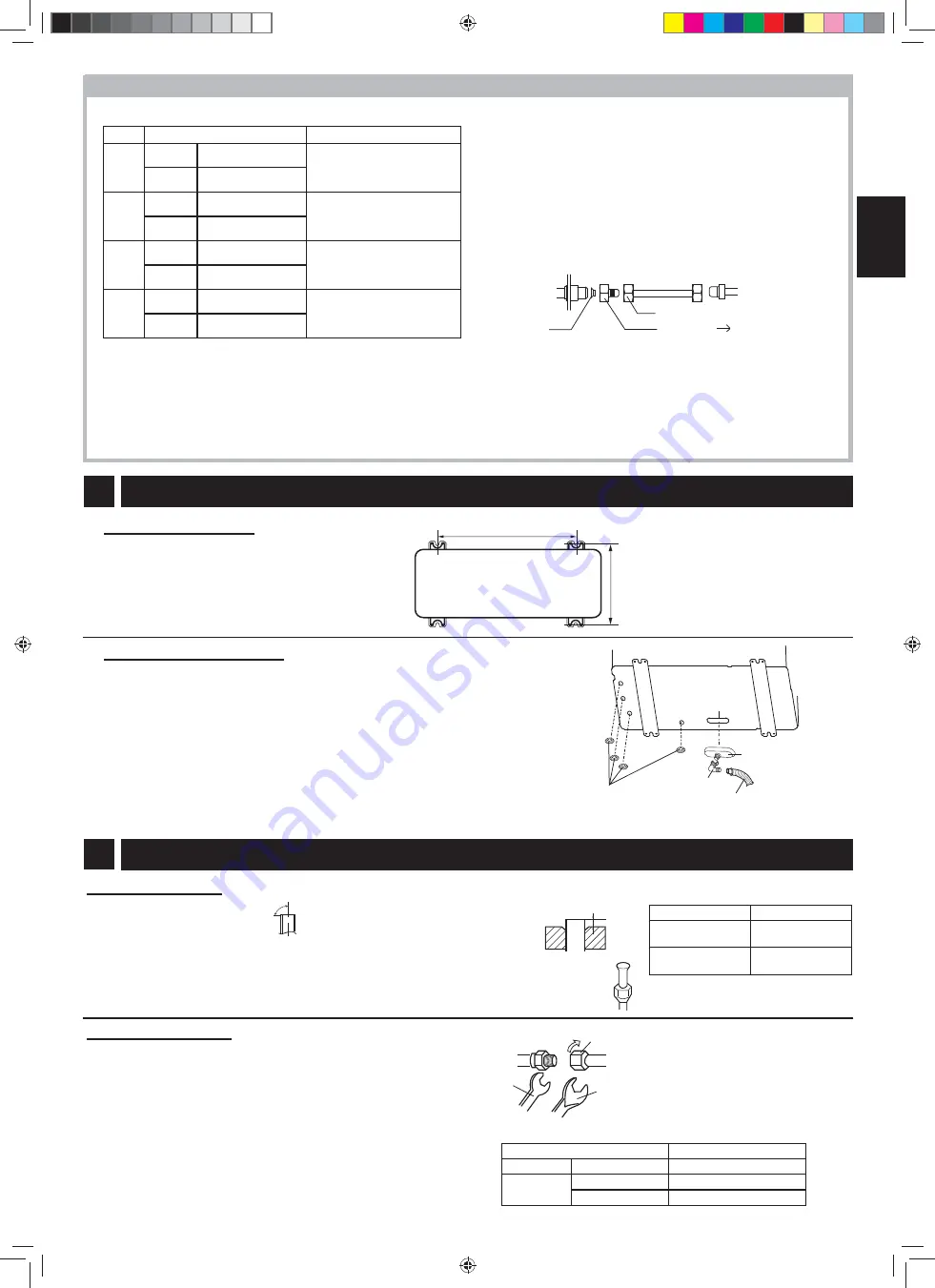

Connecting the drain hose

• In the heating mode, the outdoor unit discharges water due to

defrosting from its drain port and drain hole. Perform drain work if

water drops are a problem.

• In very cold areas where the water in the drain hose could freeze, do

not use a drain hose and the base pan cap with the outdoor unit.

(1) Insert the base pan caps into the drain holes on the bottom of the

outdoor unit.

(2) Fit the drain joint into the drain tray and insert drain tray to the drain

port.

(3) Connect commercial drain hose to the drain joint.

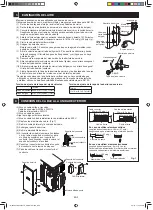

Installation dimension

Referring to the fi gure, fi rmly fasten the

outdoor unit with bolts.

Install the indoor unit according to the following table.

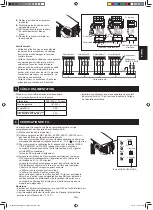

Port

Port size

Indoor unit class

D

Liquid

1/4" (ø 6.35 mm)

07 09 12

Gas

3/8" (ø 9.52 mm)

C

Liquid

1/4" (ø 6.35 mm)

07 09 12

Gas

3/8" (ø 9.52 mm)

B

Liquid

1/4" (ø 6.35 mm)

07* 09* 12* 15 18

Gas

1/2" (ø 12.7 mm)

A

Liquid

1/4" (ø 6.35 mm)

07* 09* 12* 15 18

Gas

1/2"(ø 12.7 mm)

1 OUTDOOR UNIT INSTALLATION

Drain hose (Commercially available)

Inside diameter: 5/8" (ø 16 mm)

Drain port

Drain tray

3

Drain joint

4

Note:

• Make sure the fl are nuts of the outdoor unit are securely closed for those not connected to the indoor unit.

• Install at least 3 indoor units.

Exceptionally, in the case of following combination, it is possible to install 2 units.

15 class + 18 class

18 class + 18 class

Joint (1/2"

3/8")

Seal ring

Flare nut (3/8")

Outdoor unit

Indoor unit

PORT SIZE OF THE OUTDOOR UNIT

Base pan cap

2

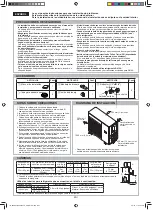

Connecting the pipes

Connect the pipes for the indoor unit first and then for the

outdoor unit.

(1) Tighten the fl are nuts by hand for the fi rst 3-4 turns.

(2) Use a spanner and torque wrench to tighten up the pipes.

• Do not over tighten the pipes; it may be deformed or

damaged.

Notes:

• Bend the pipes carefully as not to damage them.

• Lay the drain hose below the pipes.

(4) Flaring

Flare

processing

dimensions(A)

(5) Checking

To

be

fl ared perfectly circular.

Flare nut not missing.

Flare nut

Flaring the pipe end

(1) Cutting with a pipe cutter

Cut at a right angle.

(2) Deburring

Allow no cuttings in the pipe.

(3) Putting in the fl are nut

90°

A

Tool

A

R410A tool

0 - 0.02 inch

(0 - 0.5 mm)

Conventional tool

0.04 - 0.06 inch

(1.0 - 1.5 mm)

Spanner

Torque wrench

Flare nut tightening torque

Pipe size

Torque

Liquid side

1/4" (ø 6.35 mm)

11.8±1.5 ft·lbf (16±2 N·m)

Gas side

3/8" (ø 9.52 mm)

28.0±3.0 ft·lbf (38±4 N·m)

1/2" (ø 12.7 mm)

40.6±3.7 ft·lbf (55±5 N·m)

2 CONNECTING THE REFRIGERANT PIPES

* In the case of connecting 07, 09,12 class to the port A and B,

use the reducer supplied with the unit as directed below.

Connecting a pipe of 3/8"(ø 9.52 mm) to the port for

1/2"(ø 12.7 mm).

1.9 ft (590 mm)

1.2 ft (361 mm)

IM_A3AEX4M3PU(B434)_EN+FR+ES.indb EN-2

IM_A3AEX4M3PU(B434)_EN+FR+ES.indb EN-2

2/7/13 11:05:28 AM

2/7/13 11:05:28 AM