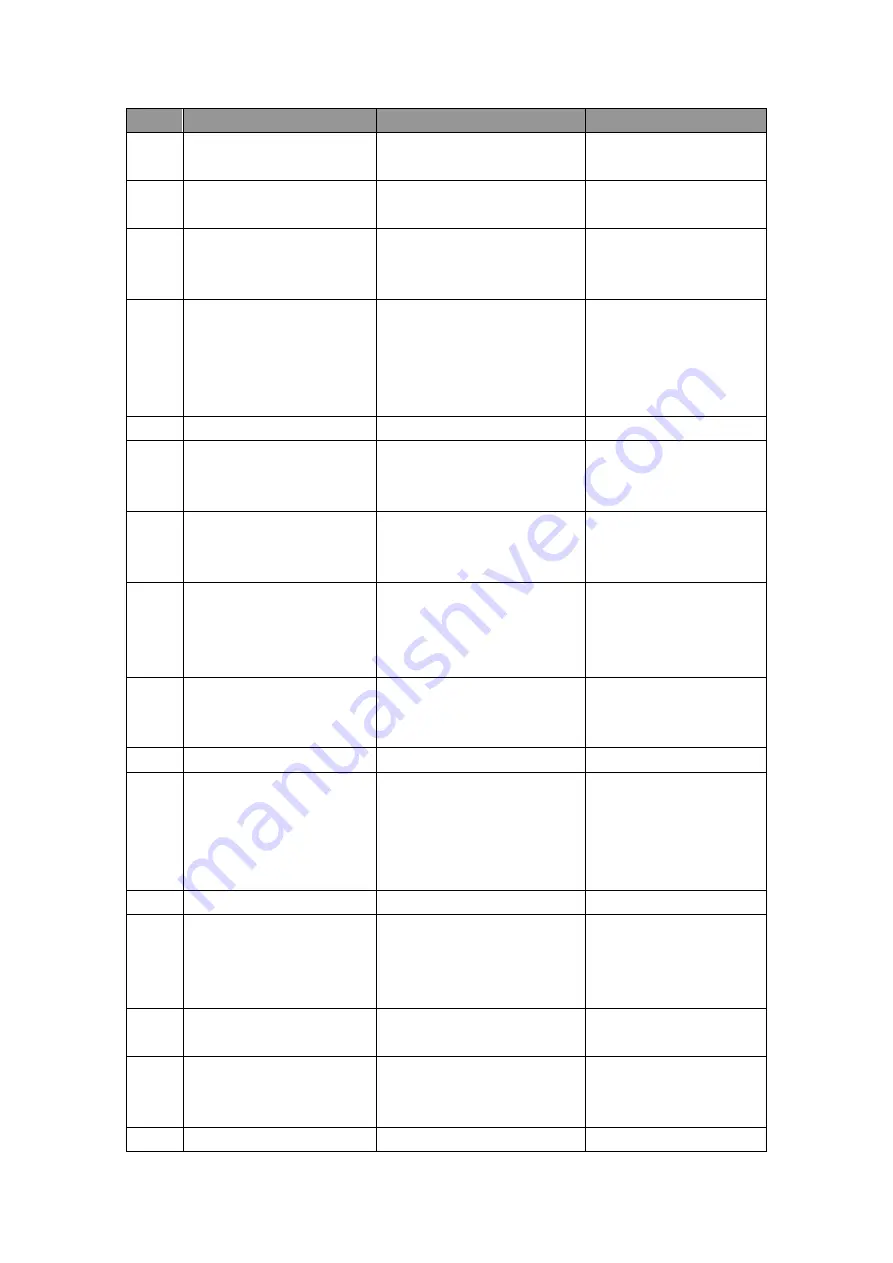

Name

Function

Method

1

Top heater

Soldering or

de-soldering BGA

Up and down to the

desired position

2

BGA angle adjust

BGA and PCB board

position

Adjust forth and

back

3

Top heater nozzle

Ensure hot air

concentration on BGA

surface

Blow to desired

position from BGA

4

Optical alignment box BGA and PCB board

position

90 degree rotate,

pull out when

positioning, push

back after finished

position

5

Light

Lighting

Adjust light position

6

CCD camera system

Pick up the image of

aligning, de-soldering

and soldering

Switch the control

button and place it

properly.

7

PCB support fixture

Fixed PCB position from

left to right position

Clockwise,

anticlockwise

rotation

8

PCB board micro

adjust X-axis

BGA and PCB board

when the X-axis

direction of the bit of

fine adjustment

PCB to the left

rotating clockwise,

counter clockwise

9

Emergency stop

button

Abnormal or special

equipment when

emergency stop

Press to stop,

Clockwise rotation

10

Light button

Lighting control

Press

11

CCD control switch

Screen image change

Switch over

AV1 shows optical

alignment image

AV2 shows camera

image

12

Start button

Starting control

Press

13

PCB board micro

adjust Y-axis

BGA and PCB board

when the Y-axis

direction of the bit of

fine adjustment

PCB backward spin

clockwise, counter

clockwise

14

Touch screen

Equipment operation

control

Hand touch-screen

15

Joy stick

Rise and fall on the

heater up and down the

left and right to zoom

Shaking the handle

up and down

16

Sensors

Measure the actual

Connect an external

Содержание ACHI-HR15000

Страница 1: ...ACHI HR15000 Rework Station NO ACHI HR 15000 Instruction Manual Shenzhen Scotle Technology Co Ltd...

Страница 6: ...4 Introduction of the main structure...

Страница 24: ...The vacuum pen is sucking the chip Laser position the red light point in the center of chip...

Страница 25: ...Optical alignment Machine testing for customers...

Страница 26: ......