Installation

02.00 | SWS-L | Assembly and operating manual | en | 0389037

23

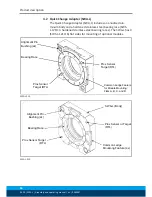

5.3 Tool Stand Design

NOTICE

Tool stand design is critical to proper operation of the SWS-L. Im-

properly designed tool stands can cause misalignments that will

cause jamming and/or excessive wear of SWS-L components.

SWS-L-1210:

Z-Compliance is required for the Tool Stand, in or-

der to ensure that the SWK-L remains fully contacted with the

SWA-L prior to issuing the Unlock command.

NOTICE

During coupling and lock-up the tool stand must allow for

movement (float) in a plane parallel to the mating surfaces of

the SWK-L and SWA-L, and in a direction perpendicular to this

plane, towards the SWK-L.

In most cases, the SWA-L are stored in a Tool Stand when not be-

ing used by the robot. During coupling and lock-up, the Tool Stand

must allow for movement (float) in a plane parallel with the mat-

ing surfaces of the SWK-L and SWA-L (X and Y directions). Even

slight misalignment between the SWK-L and SWA-L can generate

high forces during lockup if the SWA-L is not allowed to float into

place during lock-up. These high forces can cause excessive wear

and even jamming of the end-effector and robot. The degree of

float required depends on the accuracy of the robot’s positioning

and the repeatability of the SWA-L location in the Tool Stand dur-

ing lock-up. See following Figure and Table for recommended max-

imum allowable float (offsets) prior to coupling. The Tool Stand

should be designed to minimize misalignment during coupling and

uncoupling. In some cases, greater offsets than shown in the Table

can be accommodated by the SWK-L and SWA-L, but will increase

wear.

Ideally, the SWA-L should be hanging vertically in the tool stand so

that gravity acts to uncouple the SWA-L from the SWK-L during un-

locking.

SWS-L-1210:

, the Tool stand should have compliance in the Z dir-

ection. The robot should be programmed to fully seat the SWA-L in

the Tool Stand before issuing the Unlock command. The Unlock

sensors need to be active before pulling the SWK-L away.

It is possible to design Tool Stands that hold SWA-L in the hori-

zontal position, but care must be taken that the necessary compli-

ance is provided during coupling and uncoupling. In general, “hori-

zontalposition” Tool Stands cause more wear on the locking mech-

anism and locating features of the SWA-L and Tool Stand.