Technical Data

02.00 | SWS-L | Assembly and operating manual | en | 0389037

11

3 Technical Data

Designation

Description

SWS-L

210

310

510

1210

Suggested Payload

[kg]

The mass attached to the

Tool Changer.

300

510

700

1350

Working temperature

[°C]

5 – 60

5 – 60

5 – 60

5 – 60

Operating pressure

[bar]

Locking mechanism sup-

ply pressure operating

range. Supply to be clean,

dry, and filtered to 50 mi-

cron or better.

5 – 6.9

5 – 6.9

5 – 6.9

5 – 6.9

Coupling Force @ 5,5

bar [N]

Axial holding force.

31,000

38,000

62,000

93,000

Max. Moment

Load [Nm]

(X, Y) Maximum recommended

working load for optimum

performance of the Tool

Changer.

8,100

9,900

14,700

16,200

(Z) Torsion

6,900

9,600

10,500

16,200

Positional Repeatab-

ility [mm]

Repeatability tested at rated

load at one million cycles.

0.015

Weight [kg]

(coupled, no modules)

Total

8.2

20.4

28

28

SWK-L

5.4

12.7

19.3

18

SWK-A

2.7

7.7

8.7

10

Max.

Recommen-

ded

distance

between SWK-L and

SWA-L [mm]

No-Touch™ locking techno-

logy allows the SWK-L and

SWA-L to lock with separa-

tion when coupling.

2.5

2.5

2.5

1

Designation

Description

SWS-L

210

310

510

1210

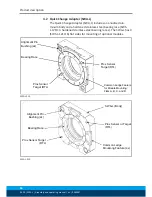

Mounting/

Customer

Interface

SWK-L

Meets

ISO 9409-1-A125

Meets

ISO 9409-1-A200

Also Supports

ABB ISO Pattern

Meets ISO 9409-

1-200-6-M12

(Position 11)

Assembly

drawings

[

}

52]

SWA-L

Meets ISO

9409-1-A125

Also supports (8)

Fasteners on 160

mm BC Pattern

Meets ISO 9409-

1-A200

Also Supports

(6) Fasteners on

ABB ISO Pattern

ISO 9409-

1-200-12-M16

(Position 12)

Assembly

drawings

[

}

52]