Inductive position measuring system PMI

•

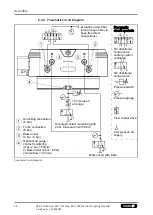

Put the sensor into programming mode

- Press the key for about 1.5 sec

- the yellow LED flashes (2 Hz)

•

Teaching in switching window 1 (yellow LED (S1) flashes)

- Place the measuring cam in the required position

- Press the key again

The position is taught in (switching window ±0.25 mm)

(the LED goes out for a short while and confirms successful

teaching in by briefly lighting up for about 1.5 s)

•

Teaching in switching window 2 (yellow LED (S2) flashes)

- Place the measuring cam in the required position

- Press the key again

The position is taught in (switching window ±0.25 mm)

(the LED goes out for a short while and confirms successful

teaching in by briefly lighting up for about 1.5 s)

• The sensor then goes back to its normal operating mode. The

LEDs of the teaching device now respond according to the

switching state of the respective output.

• An unsuccessful teach-in process (e.g. in the case of a teach-in

attempt beyond the range of measurement) is indicated by the

LED flashing rapidly (16 Hz, for 1.5 s). The previous switching

limits are kept.

• By pressing the key for 6.5 sec, the sensor can be reset to the

factory settings.

• If the voltage supply is disconnected or the key is not pressed

for more than 6 minutes during the programming process, the

programming process is stopped without changing the previous

limits.

• Programming is generally only possible in the first 6 minutes

after switching on the sensor. The programming is then blocked.

To re-enable programming, the sensor must be disconnected

briefly from the power supply.

37

09.00 | NSR maxi 220 / PKL maxi 220 | VERO-S robot coupling for pallet

handling | en | 0489051

Содержание NSR maxi 220

Страница 46: ...Appendix 46 09 00 NSR maxi 220 PKL maxi 220 VERO S robot coupling for pallet handling en 0489051 13 Appendix ...

Страница 47: ...Appendix 47 09 00 NSR maxi 220 PKL maxi 220 VERO S robot coupling for pallet handling en 0489051 ...

Страница 49: ......

Страница 50: ......

Страница 51: ......