EN

Operating instructions pages 1 to 12

Original

1

MZM 100

MZM 100 B

Operating instructions

Solenoid interlock

EN

1

1. About this document

1.1 Function

This operating instructions manual provides all the information you

need for the mounting, set-up and commissioning to ensure the safe

operation and disassembly of the safety switchgear The operating

instructions must be available in a legible condition and a complete

version in the vicinity of the device

1.2 Target group: authorised qualified personnel

All operations described in this operating instructions manual must

be carried out by trained specialist personnel, authorised by the plant

operator only

Please make sure that you have read and understood these operating

instructions and that you know all applicable legislations regarding

occupational safety and accident prevention prior to installation and

putting the component into operation

The machine builder must carefully select the harmonised standards

to be complied with as well as other technical specifications for the

selection, mounting and integration of the components

1.3 Explanation of the symbols used

Information, hint, note:

This symbol is used for identifying useful additional information

Caution:

Failure to comply with this warning notice could

lead to failures or malfunctions

Warning:

Failure to comply with this warning notice could

lead to physical injury and/or damage to the machine

1.4 Appropriate use

The products described in these operating instructions are developed

to execute safety-related functions as part of an entire plant or machine

It is the responsibility of the manufacturer of a machine or plant to

ensure the correct functionality of the entire machine or plant

The safety switchgear must be exclusively used in accordance with

the versions listed below or for the applications authorised by the

manufacturer Detailed information regarding the range of applications

can be found in the chapter "Product description"

1.5 General safety instructions

The user must observe the safety instructions in this operating

instructions manual, labelled with the caution or warning symbol above,

the country-specific installation standards as well as all prevailing safety

regulations and accident prevention rules

Further technical information can be found in the Schmersal

catalogues or in the online catalogue on the Internet:

wwwschmersalnet

The information contained in this operating instructions manual is

provided without liability and is subject to technical modifications

Content

11 Function 1

12 Target group: authorised qualified personnel 1

13 Explanation of the symbols used 1

15 General safety instructions 1

23 Comprehensive quality insurance to 2006/42/EC 2

24 Purpose 2

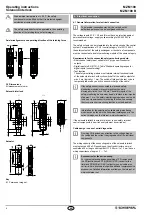

3 Mounting

31 General mounting instructions 3

32 Dimensions 4

41 General information for electrical connection 4

5 Operating principles and latching force adjustment

51 Mode of operation of the safety outputs 5

52 Description of the latching force adjustment 5

62 Solenoid interlock with conventional diagnostic output 6

63 Solenoid interlock with serial diagnostic function 8

x

000 / 08

2018 / v

A

- 103013109-EN / H / 2018-08-15 /

AE-Nr

9800

82 Disposal 9

9 Appendix