3

MZM 100

MZM 100 B

Operating instructions

Solenoid interlock

EN

2.5 Technical data

General data:

Standards:

IEC 60947-5-1, IEC 60947-5-3, ISO 14119,

ISO 13849-1, IEC 61508

Material of the housings:

Plastic, glass-fibre reinforced thermoplastic,

self-extinguishing

Working principle:

inductive

Coding level according to ISO 14119:

low

Response time:

≤ 150 ms

Duration of risk:

< 150 ms

Time to readiness:

< 4000 ms

Actuator:

MZM 100-B11

Series-wiring:

Unlimited number of components,

please observe external cable protection,

max 31 components in case of serial diagnostics

Length of the sensor chain:

max 200 m;

- Note:

Cable length and cable section alter the voltage drop

depending on the output current

Mechanical data:

Execution of the electrical connection:

- ST:

M23 connector, (8+1) poles,

- ST2:

M12 connector, 8 poles

Tightening torque of the fixing screws:

8 N

m

Electrically adjustable latching force (RE), typically:

30 N … 100 N

Permanent magnet (M), typically:

15 N

Holding force F

max

typically:

750 N

Holding force F guaranteed:

500 N

Mechanical life:

≥ 1,000,000 operations

(for safety guards ≤ 5 kg and

actuating speed ≤ 0.5 m/s)

Switching distances to IEC 60947-5-3:

Assured switching distance s

ao

:

0 mm

Assured switch-off distance s

ar

:

1 mm

Ambient conditions:

Ambient temperature:

−25 °C … +55 °C

Storage and transport temperature:

−25 °C … +85 °C

Relative humidity:

30% … 95%,

no condensation, no icing

Protection class:

IP65 / IP67

Protection class:

III

Resistance to shock:

30 g / 11 ms

Switching frequency:

1 Hz

Resistance to vibration:

10 150 Hz, amplitude 035 mm / 5 g

Insulation values to IEC 60664-1:

- Rated insulation voltage U

i

:

32 VDC

-

Rated impulse withstand voltage U

imp

:

08 kV

-

Over-voltage category:

III

-

Degree of pollution:

3

Switching frequency:

1 Hz

Electrical data:

Operating voltage U

B

:

24 VDC −15% / +10%

(stabilised PELV units to IEC 60204-1)

Operating current device:

max 06 A

- Note:

plus current through the safety outputs

Magnet switch-on time ED:

100 %

Rated operating voltage U

e

:

24 VDC

Rated operating current I

e

:

1 A

Required rated short-circuit current:

100 A

Device fuse rating:

2 A

Electrical data – Safety inputs:

Safety inputs:

X1 and X2

Switching thresholds:

− 3 V … 5 V (Low),

15 V … 30 V (High)

Accepted test pulse duration on input signal:

≤ 1.0 ms

- With test pulse interval of:

≥ 100 ms

Classification:

ZVEI CB24I

Countersink:

C1

Source:

C1

C2

C3

Electrical data – Safety outputs:

Safety outputs:

Y1 and Y2

Switching elements:

normally open function, 2 channel,

OSSD, p-type

Fuse rating:

short-circuit proof

Utilisation category:

DC-13: U

e

/I

e

: 24 VDC / 025 A

Rated operating current I

e

:

each max 025 A

Leakage current I

r

:

≤ 0.5 mA

Voltage drop U

d

:

< 1 V

Test pulse duration:

≤ 1.0 ms

Test pulse interval:

1000 ms

Classification:

ZVEI CB24I

Source:

C1

Countersink:

C1

Electrical data – Diagnostic output:

Diagnostic output:

OUT

Switching element:

p-type, short-circuit proof

Utilisation category:

DC-13: Ue/Ie: 24 VDC / 005 A

Wiring capacitance for serial diagnostics:

max 50 nF

Electrical data – Magnet control:

Magnet control:

IN

Switching thresholds:

− 3 V … 5 V (Low),

15 V … 30 V (High)

Current consumption per input:

typical10 mA / 24 V, dynamic 20 mA

Accepted test pulse duration on input signal:

≤ 5.0 ms

- With test pulse interval of:

≥ 40 ms

Classification:

ZVEI CB24I

Countersink: C0

Source:

C1

C2

C3

LED status display:

green LED:

Supply voltage

yellow LED

:

Device condition

red LED:

Internal device error

Use isolated power supply only If the cable and connector

assembly is not listed for Type 12 or higher, then the device

shall be used in a Type 1 environment only

2.6 Safety classification

Standards:

ISO 13849-1, IEC 61508

PL:

e

Control Category:

4

PFH:

354 x 10

-9

/ h

SIL:

suitable for SIL 3 applications

Service life:

20 years

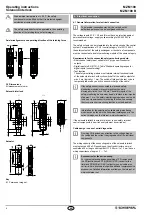

3. Mounting

3.1 General mounting instructions

Please observe the relevant requirements of the stan-

dards ISO 12100, ISO 14119 and ISO 14120

The solenoid interlock must be used as an end stop

Any mounting position The system must only be operated with an

angle of ≤ 2° between the solenoid interlock and the actuator.

For fitting the solenoid interlock and the actuator, two mounting

holes for M6 screws with washers (washers included in delivery) are

provided

After fitting, the mounting holes can be sealed by means of the supplied

plugs The plugs serve as a means of sealing the assembly openings

and are also suitable to prevent against tampering with the screw

connection

Minimum distance between two devices: 100 mm

The actuator must be permanently fitted to the safety guards

and protected against displacement by suitable measures

(eg tamperproof screws, gluing, drilling of the screw heads)