ASV115

Very simple parameterisation of complex applications

Uploading and downloading parameters to transfer configurations

from one device to another

Configurable units range

Overview page for rapid entry of the main parameters

Tree view for fast navigation through the individual configuration

pages

Integrated access to plant schematic and wiring diagram

Print-out of device configuration

Service functions for fast troubleshooting

C

C

C

A

1

0

640

Device No. 31 (max.)

120

(L > 200 m)

120

(L > 200 m)

Shielding

Control cabinet

Device No. 1

MM

MM

24V~

Device No. 2

Structured user guidance

Online monitoring of most important operation parameters

Engineering and fitting notes

The drive can be fitted in any position (including upside down). It is

placed directly on the damper shaft and clipped to the anti-torque

device. The self-centring shaft adaptor ensures gentle operation of

the damper shaft. The damper drive can be easily removed from

the damper shaft without dismantling the anti-torque device.

The angle of rotation can be limited between 0° and 90° on the

device and can be set continuously between 5° and 80°. The limita-

tion is set with a set-screw directly on the drive, and with the limit

stop on the self-centring shaft adaptor. This shaft adaptor is suitable

for damper shafts of Ø 8...16 mm,

6.5...12.7 mm.

Note

The housing must not be opened.

For feedback of the operating status, it is advisable to display the

actual value signal (air volume) in the management system.

No account has been taken of special standards such as

IEC/EN 61508, IEC/EN 61511, IEC/EN 61131-1 and 2. Local regu-

lations on installation, application, access, access authorisations,

accident prevention, safety, dismantling and disposal must be

observed. Compliance is also required with installation standards

EN 50178, 50310, 50110, 50274, 61140 and similar.

The RS-485 parameterisation interface in the housing cover is not

suitable for continuous operation. After parameterisation has been

completed, the parameter plug must be removed and the opening

should be sealed to restore the IP protection type.

Fitting outdoors

We recommend that devices are given additional protection against

the effects of weather if installed outside.

Wiring

Power supply

To ensure fault-free operation, the following wire cross-sections and

lengths must be observed for the 24 V power supply and the ground

connection.

All devices within a network segment must be supplied by the same

transformer. The power supply should be wired in star formation,

observing the max. cable length in accordance with the table below

(column 1:

1 Device

).

Maximum cable lengths for various numbers of devices

Maximum number of devices

Cross-

section

1* 8 16 24

32

0.32 mm²

50

6.2

3.2

2.0

1.6

0.5 mm²

80

10.0

5.0

3.4

2.6

0.75 mm²

120

05.0

7.6

5.0

3.8

1.00 mm²

160

20.0

10.0

6.6

5.0

1.50 mm²

240

30.0

15.0

10.0

7.6

*) Star formation recommended.

Analogue signals

Analogue and digital signals are connected via the power cable. To

ensure perfect operation, the ground cable (for drives that are

interconnected in order to exchange signals) must be on the same

potential.

The maximum cable length for analogue signals is dependent

mainly on the voltage drop on the ground cable. A signal cable with

a resistance of 100

results in a 10 mV voltage drop with an

ASV115 connected. If ten ASV115s are connected to this cable in

series, the resultant voltage drop is 100 mV or an error of 1%.

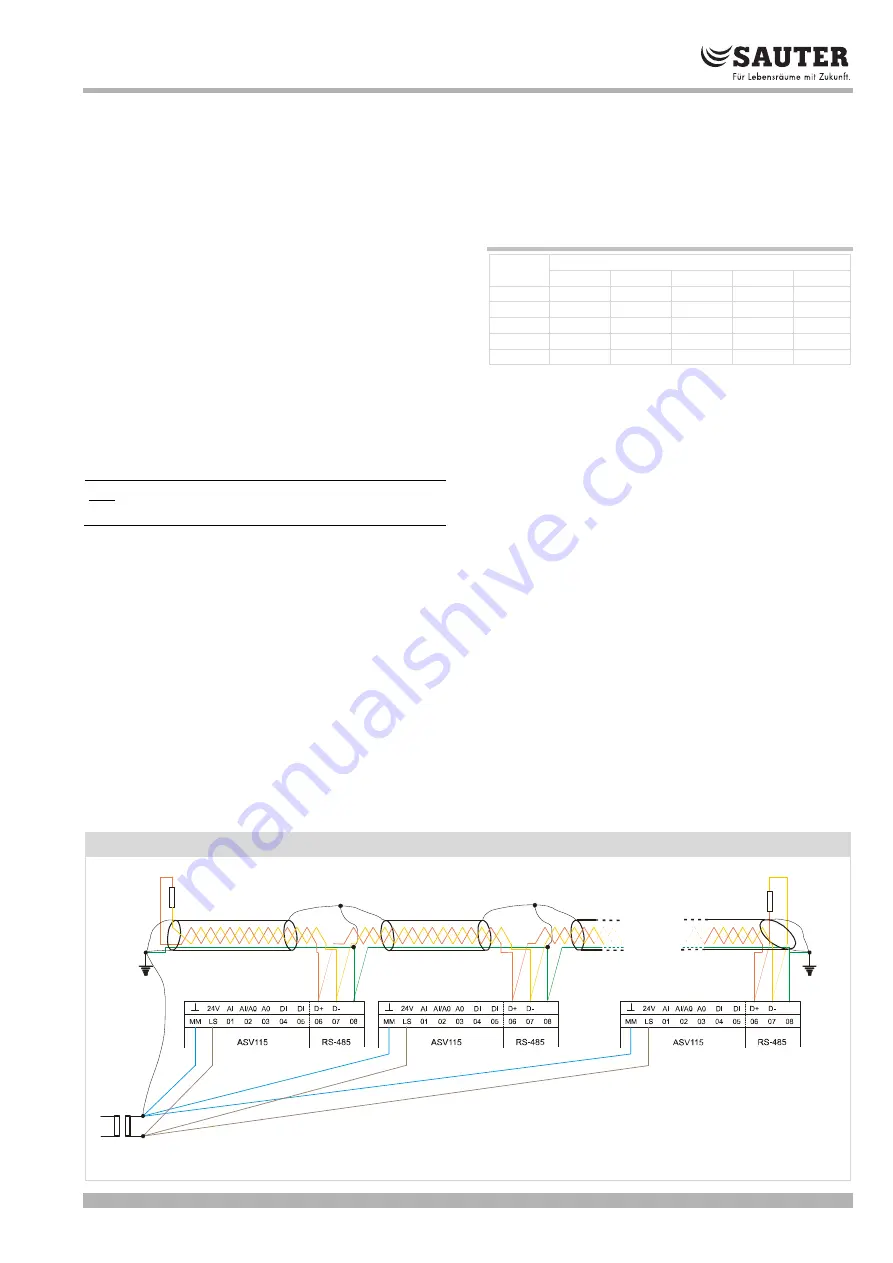

SLC bus connection

The integrated SLC bus is physically specified as an RS-485 inter-

face. Depending on the line length, up to 31 devices can be con-

nected within one network segment. On all the controllers, the

terminals C08 should be linked together and have the same poten-

tial. Neither special cables nor terminating resistors are required for

cabling < 200 m. The wiring should have a purely line topology

(daisy chain). Stub cables are not permitted; however, if they can-

not be avoided, they should be limited to a maximum of 3 metres.

Wiring diagram (SLC bus)

www.sauter-controls.com

7/13