10

SLIDE PLUMBING INSTRUCTIONS

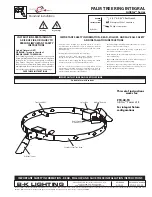

1.

Thread the nipple (9) into swivel (10).

2.

Note the angle of the threaded hole in the top

runway section.

3.

Align the nipple with the hole-angle from the

outside of the slide as shown in the top

illustration.

4.

Insert the nipple into the slides hole and firmly

thread the nipple using the swivel (10) to turn.

**This action is self-sealing and no Teflon or

Plumbing glue is required**

5.

Note the pressure required as you turn the fitting

assembly, this is letting you know a tight fit is

being formed.

**The fitting material is harder than the slide material

and makes its own threading; that is why it is good to

get this right the first time, but not imperative**

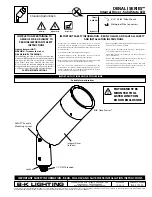

6.

Turn the fitting assembly (9 & 10) until the swivel

(10) comes in contact with the wall of the Cyclone

7.

Gently tilt the swivel (10) away from the slide and

complete one more turn to ensure a good

insertion.

8.

Finish turning the swivel (10) with the fitting

assembly pointed back toward the bottom of the

stairs as shown in the bottom illustration.

**Threads still showing between the nipple

(9) and slide wall after step 8 (above) are

better left exposed than over tightening

and stripping the hole or scraping the slide

wall with the swivel (10)**

9.

Place the hose clip in a location where

it will support the hose without putting

a “kink” into its shape; screw it directly

into the slide stairs making sure not to

over tighten the screw.

**The purpose of the clip is to take shock

transferred through the hose from sudden

jerks**

10.

Turn on the water so that it lands in the

center of the slide runway and ENJOY

Nipple (9)

Swivel (10)

Outside Runway

Inside Runway

Outside Runway

Inside Runway

Contact?

Stop!

Содержание CYCLONE

Страница 5: ...5 ASSEMBLED CYCLONE LAYOUT FIGURE A...