19

INSTALLATION—ALUMINUM HOOD (OPTIONAL)

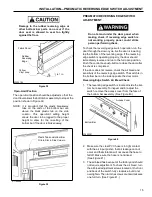

2. Align the photo eyes on the front side of the door.

(See Figure 50.)

3. Adjust the photo eyes on the rear side of the door

as required, dependent on the type of mounting

used by the installer.

NOTE: Pre-drilled mounting holes have been pro-

vided in the side columns to mount the

photoeyes. However, it is important to verify

with the customer what type of equipment

is moving through the door. Large

equipment may allow the photoeye beam

to shoot under the equipment causing the

door to close on the equipment. Different

mounting locations may be required.

ALUMINUM HOOD (OPTIONAL)

NOTE: The following procedure is required

only if your door was shipped with an

optional hood assembly.

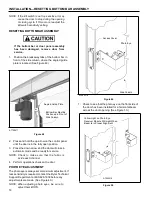

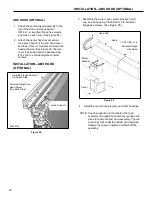

Self-Tapping

Sheet Metal

Screw

A7500047

Centerline of

Head Extrusion

and Center Cover

Figure 52

Center Cove

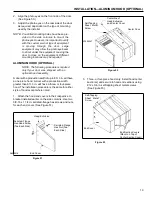

A door with a production width of up to 8 ft. 3 in. will have

a one-piece hood. A door with a production width

greater than 8 ft. 3 in. will have a three- or four-piece

hood. The installation procedure is the same for either

style of hood except where noted.

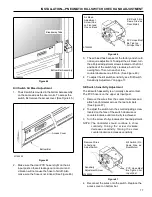

1. Attach the hood end covers to their respective U-

bracket installed earlier on the side columns. Use two

3/8-16 x 1 1/4-in. serrated-flange hex screws and nuts

for each end cover. (See Figure 51.)

3. Three- or four-piece hood only: Install hood center

section(s) and secure to hood end sections using

#12 x 3/4-in. self-tapping sheet metal screws.

(See Figure 53.)

Self-Tapping

Sheet Metal

Screw

Head Extrusion

Serrated-Flange

Hex-Head Screw

(Two Each Side)

Serrated-Flange

Hex Nut (Two

Each Side)

End Cover

End Section Covers

(Mount on Top of

Center Section Cover)

A8500016

End Cover

Figure 51

Figure 53