9

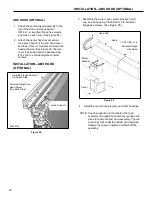

INSTALLATION—HEAD ASSEMBLY

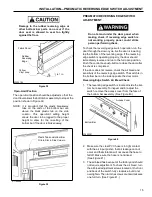

Figure 19

7. Bolt the flange bearing assembly to the side column using

two 1/2-13 x 1-1/4-in. serrated-flange hex screws and nuts

(or two 1/2-13 x 2-in. screws and nuts if spacers are

required, or nuts only if 6-in. screws were installed earlier).

DO NOT tighten the hex nuts at this time.

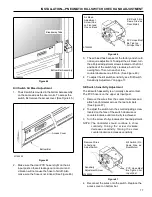

IMPORTANT: If the drum/fabric roll assembly

cannot be made level by adjusting the flange

bearing mounting bracket up or down, verify that

the side columns are plumb, square and level and

make any necessary adjustments.

8. Place a carpenter’s level along the length of the

drum/fabric roll assembly and adjust the flange

bearing mounting bracket up or down, as required,

until the drum/fabric roll assembly is level.

Tighten the hardware securing the motor and the

flange bearing mounting brackets to the side

columns. Then tighten the set screw to lock the

flange bearing to the drum shaft. (See Figure 20

and Figure 21.

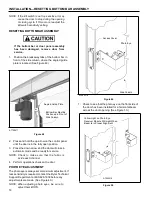

For a door with pullouts, verify that the two hex nuts

threaded on each 6-in. screw are tight against their

associated side column and mounting bracket.

Failure to tighten all eight nuts could result in

damage to the side columns. (See Figure 21.)

Figure 20

Figure 21

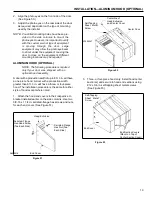

DO NOT remove the shipping bands holding the

fabric material to the drum roll assembly at this

time.

9. Do not remove the shipping bands securing the

fabric material to the drum roll. Only remove the

fasteners securing the drum assembly to the forklift.

Then lower and move the forklift out of the way.

IMPORTANT:

Install spacer between flange

bearing assembly and side column (if spacer

is supplied).

Serrated-Flange

Hex Screw

(Two Required)

Serrated-Flange

Hex Nut

(Two Required)

Flange

bearing

assembly

Head/Fabric

Roll assembly

Tighten Each

Set of Nuts on

6-in. Screws

Pullout

Mounting

Bracket

Side

Column

Tighten Hex Screws

(Tighten Hex Nuts If

Pullouts Are Used)

Tighten Flange

Bearing Set Screw

Adjust Bracket Up or

Down as Required

Level