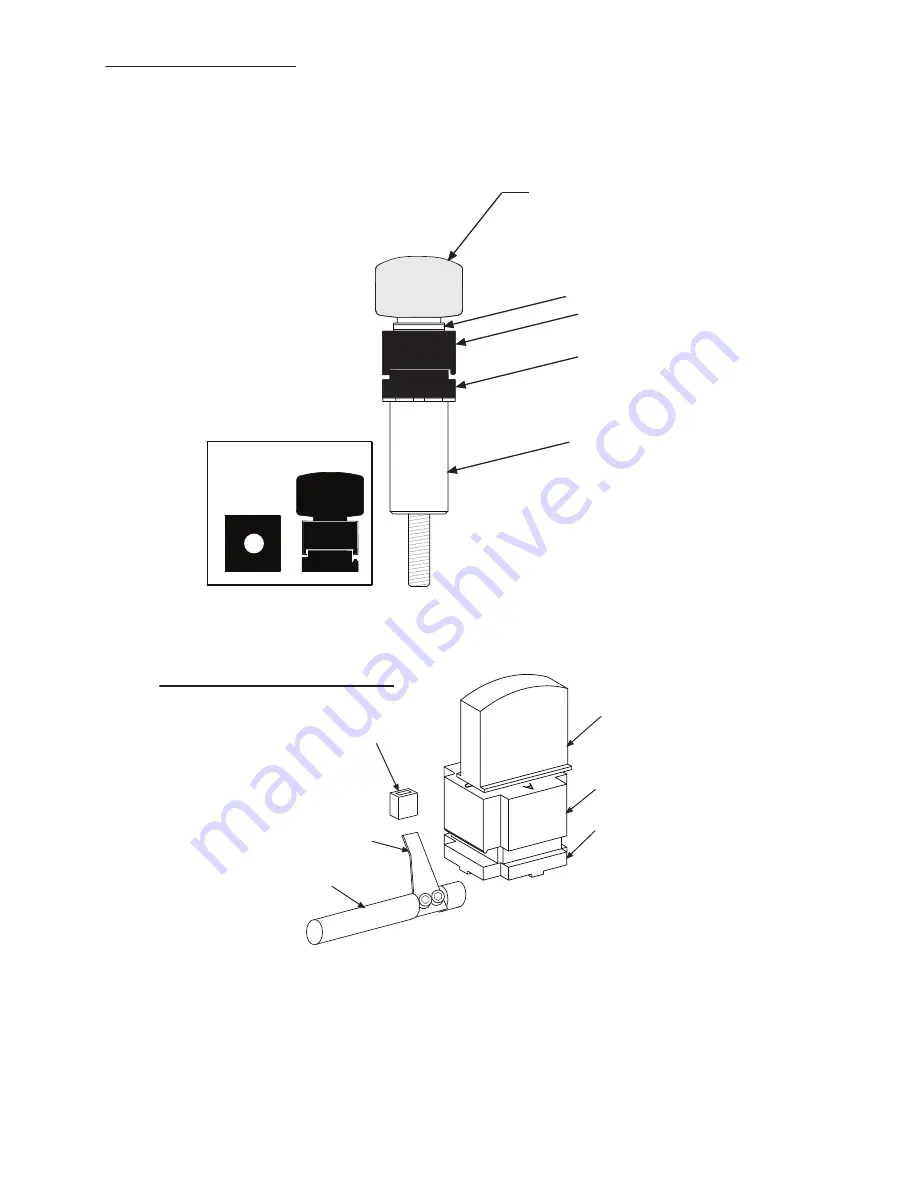

CLAMPS MORE KEYS

NEW 4-WAY VISES

A

B

C

D

RY20080 KNOB WITH SHAFT ASSY.

RY82 3-PC THRUST BEARING ASSY.

RY20089 TOP VISE, JAW 4-WAY

RY20047 BOTTON VISE, 4-WAY

RY20046 VISE PLUNGER

Fig. 4

RY10054 Key Gauge

Protector (red)

RY10049Key Gauge Shaft

RY9278 Vinyl Cap (red)

Key Gauge

RY10050 Left-Hand Key Gauge

RY10048 Right-Hand Key Gauge

Key Vise Knob

(

with)

RY82

3-piece Thrust

Bearing Assy.

Top 4-way Jaw

Bottom 4-way Jaw

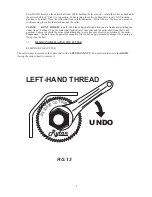

VISE JAW REPLACEMENT

Vise jaws (cartridges) are replaced in pairs as an assembly, a matched set consisting of (one top jaw and one bottom jaw),

you will need two sets for your key machine. You will disassemble and re-install the old plungers, springs, and screws.

Or you can buy a complete set with the plunger, top jaw, bottom jaw, screws and springs. Simply drop the (cartridges)

in place, you will need two cartridges. You will reuse your RY2008 Knob with Shaft assy., and the RY82 thrust bearings.

Coat all steel sliding surfaces with a light coating of grease when installing the vises.

8.

TOP SHOULDER KEY GAUGING

Standard cylinder keys should always be top shoulder gauged. Use the machine’s full-function flip-up key gauges.

We do not recommend bottom shoulder gauging because key blank manufacturers do not always maintain a reliable

correlation between bottom and top shoulder positions on the key blanks they make.

Always remember to flip DOWN your key gauges before cutting a key. Failure to do will prevent your key machine from

cutting the key.

5

Fig. 3