10

START-UP

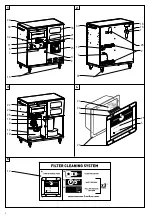

Turbine positioning (Fig. 3)

- The machine must be positioned on a solid surface

- The turbine vents must be kept clean and unclogged (2).

- Lock the brakes before each use (13).

- The exhaust (34) can be connected with the exterior (Ø 63

mm).

Power supply

- Turn the main switch (4) to “O” (off) before connecting this

appliance to the supply mains;

- supply mains voltage and frequency must match the

identification plate(18);

- connect to power socket outlets provided with earth

conductor and adequate protections.

Compressed air mains (To supply pneumatic tools)

- Do not exceed 6 bar;

- dehumidified and filtered air required;

- connect the appliance to the compressed air main with an

hose suitable for the air pressure and int. diam. 10 mm min.

Assembling the two-way link (29)

Insert the adaptor in the inlet nozzle (11).

Electrical tool connections

- Check for the tool switch turned off before connecting it to

the front panel socket outlet;

- insert the tool plug into the front panel socket (6) (pic. 7)

(AUTOMATIC plug only);

- connect the tool to the swivelling nozze with the hose

(pic. 9);

- do not plug electric tools exceeding the power indicated on

the front panel.

Pneumatic tool connections

- Check for the tool switch turned off before connecting it to

the front panel quick coupling;

- connect the tool to the appliance with the quick couplings (7)

(pic. 6) and (8) (pic. 8);

- connect the coaxial hose (optional) to the quick coupling

(pic.6).

Check the tool functioning as indicated on their instructions

manual.

Preliminary checks

- Check that the dust collection bag (12) has been fitted in the

container (10);

- check the dust container is correctly placed inside the unit

(fig. 11):

- check that the vacuum hose is properly fixed and does not

hinder tool movement;

- check that there are no leaks in the compressed air supply

system.

MACHINE USE

The machine can operates in manual or automatic mode: to

select the mode, turn the switch (4) to the right (automatic

mode) or to the left (manual mode) (pic. 4).

The green indicator (5) turns on when the vacuum motor starts.

Using the machine in automatic mode (A)

Pneumatic connections and electric AUTOMATIC plug

Automatic operations means that the vacuum starts when an

electrical or pneumatic tool is turned on.

The vacuum will automatically turn off eight seconds after the

tool is turned off.

Electric SERVICE plug (15)

Electric SERVICE plug is supplied. When the tool connected to

the socket is turned on, the vacuum does not start.

Using the machine in manual mode (M)

Manual operations means that the vacuum runs continuously.

Power on the front panel outlet sockets is permanently active

during manual running.

MAINTENANCE

A yearly technical check on parts and filtering system by an

authorized service centre is required.

TURBINE ON indicator (pic. 4)

The green indicator turns on when the vacuum starts.

Inside the electric control board a motor electric protection is

installed (27).

When the TURBINE ON indicator turns on and the vacuum

motor is blocked, contact an Authorized Service Centre.

FILTER CHECK indicator (pic. 20)

A manual filter cleaning system is installed inside the unit.

When FILTER CHECK (25) indicator light turneds on, a manual

filter cleaning operation is required.

Manual filter cleaning system (pic. 5)

Follow the instruction on the filter cleaning label to correctly per-

morm a cleaning operation:

a) Turn the cleaner in manual mode (pic. 5A)

b) Close the suction (pic. 5B)

c) Wait 5 “ (pic. 5C)

d) Pull and release to clean (pic. 5D)

Repeat operations c and d 3 times

When the FILTER CHECK indicator light turneds off, the filter

efficiency condition is correct.

Ordinary check operations

For user servicing, the appliance must be dismantled, cleaned

and serviced, as far as it is reasonably practicable, without

causing risk to the maintenance staff and others.

Suitable precautions include, decontamination before

dismantling, provision for local filtered exhaust ventilation where

the appliance is dismantled (according to local regulations),

cleaning of the maintenance area and suitable personal