F

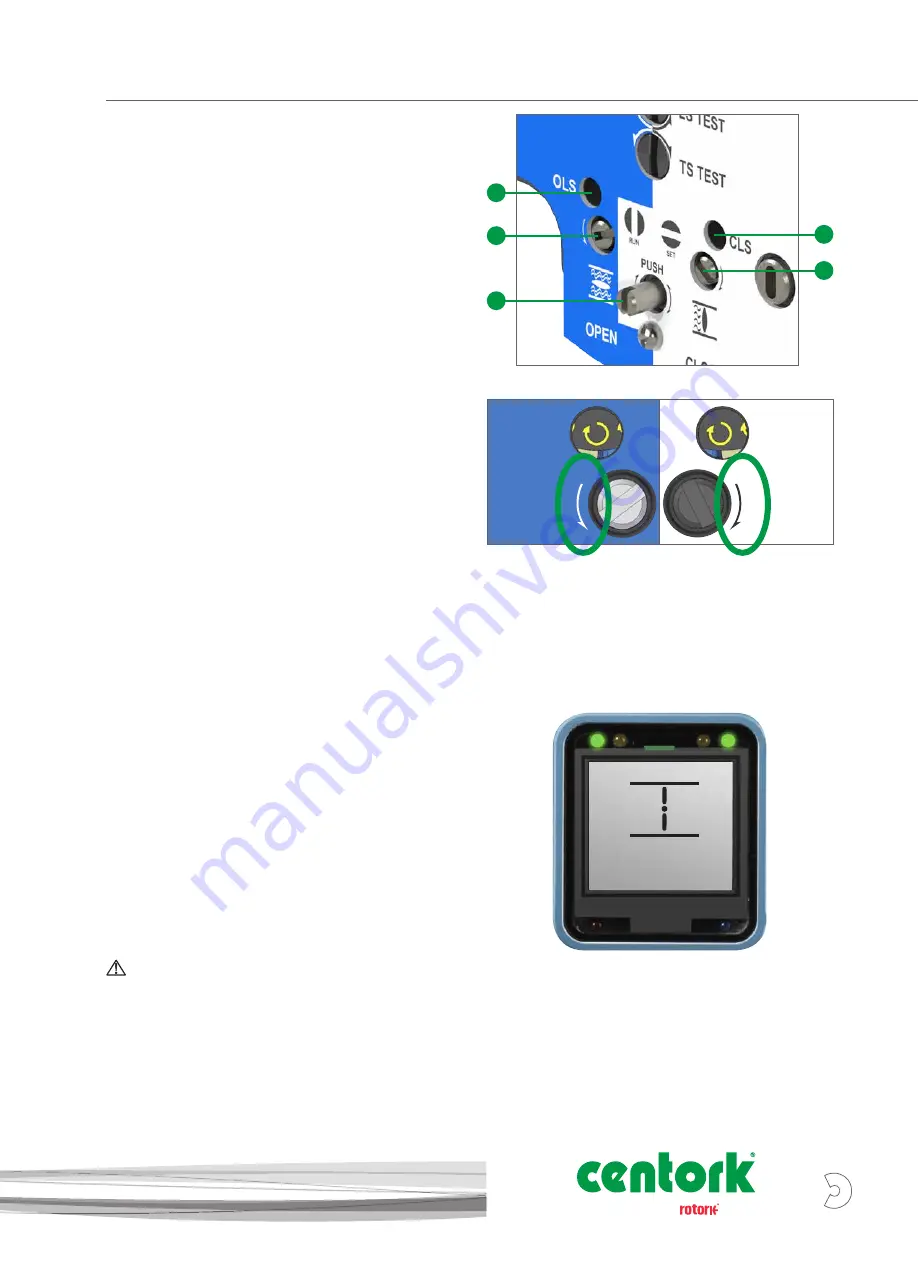

Centronik Interface - Basic Settings - Mechanical Switch Mechanism

Set Position Limits

F

OLS Indicator Window

G

OLS Adjustment Screw

H

Drive Clutch Shaft

I

CLS Indicator Window

J

CLS Adjustment Screw

1) Move actuator to the valve CLOSED position using handwheel

operation.

2) Using a flat screwdriver, depress the Drive Clutch Shaft and

rotate to “Run” position as shown on the switch mechanism

faceplate.

3) The CLS Adjustment Screw must now be rotated to make

the closed limit switch inside the switch mechanism. The CLS

Indicator Window will show one of four possible symbols.

Please refer to Figure 1 on page 16 for direction input.

4) Depending on where the mechanism is in the cycle, it is

possible that the switch will be approached from the wrong

direction, in which case it is necessary to move through the

limit and approach it from the correct direction. This is done to

avoid the need to wind through the whole mechanism to reach

the limit position. The correct direction to approach the limit is

shown by the arrow next to the Adjustment Screw input.

5) Perform two checks to confirm the CLOSED limit position

switch has been made correctly.

a. The feel of the Adjustment Screw will noticeably change

providing more mechanical resistance at the switching

point of the contact.

b. Confirm the switch has been made by checking the

CLOSED limit symbol is shown on the Centronik display.

6) Using a flat screwdriver, depress the Drive Clutch Shaft and

rotate to “Run” position as shown on the switch mechanism

faceplate.

7) Rotate the CLS and OLS Adjustment Screws a small amount in

both directions to re-engage the mechanism drive. A click will

be heard as the drive drops back into engagement and the

adjustment screws will no longer move in either direction.

This must be done or the limit will be lost when the

actuator is moved.

G

H

I

J

CLOSELIM

DEMO

CLS

OLS

A4

US

US

A4

US

A4

US

A4

A4

US

US

A4

US

A4

A4

US

15

A

Brand