ACO-4500 User Guide (v3.0)

Troubleshooting • 51

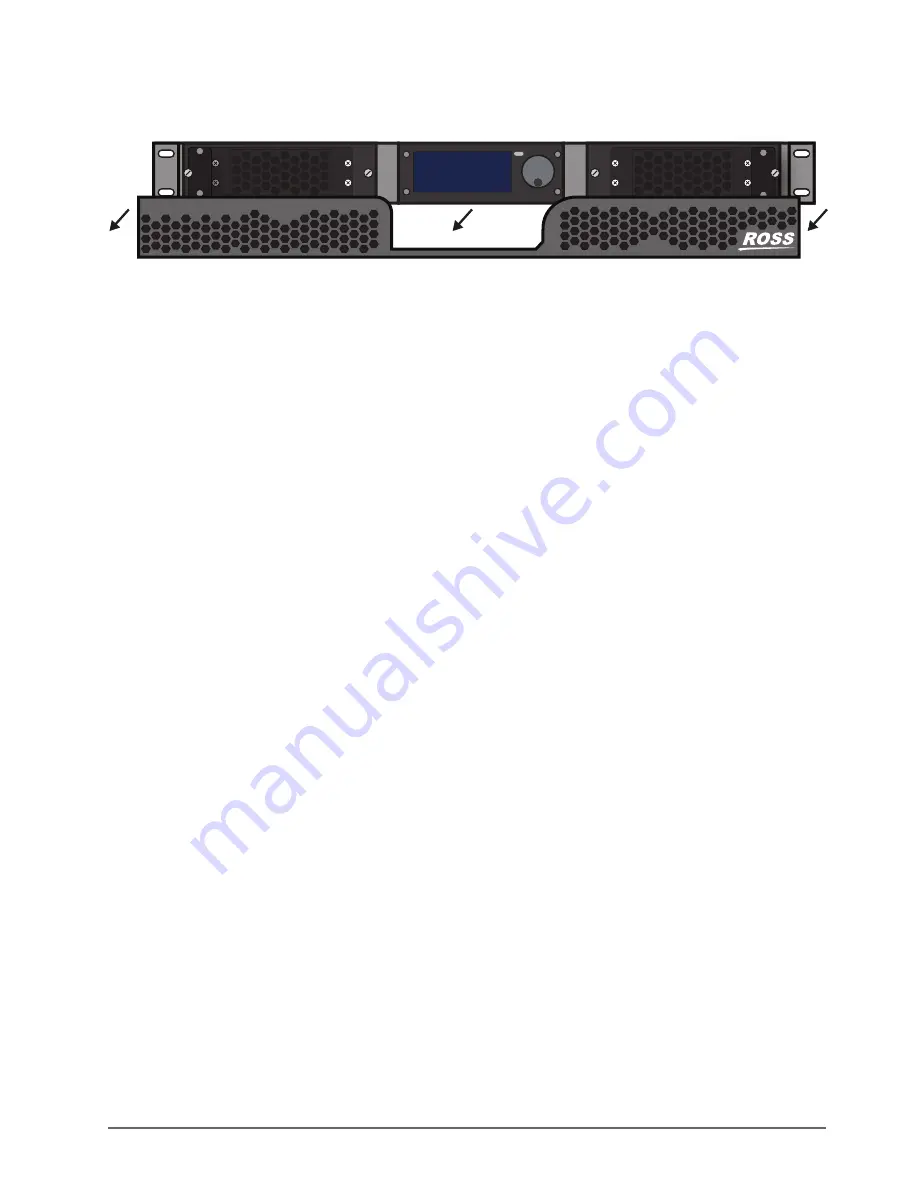

To remove the front faceplate from the main chassis

1. Remove the front faceplate by gently pulling it towards you and away from the main chassis.

Figure 8.3 Removing the Front Faceplate

2. Set the faceplate aside on a clean, static-free surface.

Removing the Failed PS-4500

A failed PS-4500 can be hot-swapped with a new PS-4500 without powering down the main chassis.

To remove a failed PS-4500

1. Use a 3/16” slotted screwdriver to disengage the captive screws that affix the PS-4500 to the main chassis.

2. Use the handles on the front of the failed PS-4500 to remove the PS-4500 by gently pulling it towards you and

away from the chassis.

3. Set the failed PS-4500 aside.

Installing the New PS-4500

The PS-4500 slides into the available slot and connects to the chassis midplane via the blue connector at its rear.

To install a new PS-4500

1. Align the new PS-4500 with its slot in the main chassis.

2. Slide the new PS-4500 into the available slot. You will feel the PS-4500 engage with the midplane.

3. Use a 3/16” slotted screwdriver to tighten the captive screws and affix the PS-4500 to the main chassis.

Re-install the Front Faceplate

You must re-install the front faceplate to the main chassis to complete the install.

To re-install the front faceplate on the main chassis

1. Position the faceplate over the power supplies.

2. Secure the faceplate on the main chassis.

Software Upgrades

This upgrade procedure applies to ACO-4500 systems where an Ethernet connection is installed. It outlines the

steps necessary to upgrade the software programmed on the main module.

Performing a software upgrade to the ACO-4500 requires the unit to be rebooted, and may be off-line for several

minutes. Ensure that your system is not in use.

ACO-4500

CHANGEOVER

Содержание 4500DR-204-03

Страница 1: ...ACO 4500 User Guide ...

Страница 6: ......

Страница 10: ...iv Contents ACO 4500 User Guide v3 0 ...

Страница 34: ...34 Getting Started ACO 4500 User Guide v3 0 ...

Страница 54: ...54 Troubleshooting ACO 4500 User Guide v3 0 ...

Страница 62: ...62 Connector Pinouts ACO 4500 User Guide v3 0 ...

Страница 68: ...68 Service Information ACO 4500 User Guide v3 0 ...

Страница 70: ...70 Glossary ACO 4500 User Guide v3 0 ...