eng

eng

3.3.

Use of the ROLLER’S Nipparo nipple holder

3

/

8

–2”

In order to hold the piece of pipe with the nipple holder Nipparo, it is

necessary to spread the head of the nipple holder by turning the spindle

with and corresponding tool (screw driver...). This may only be made

with a pipe attached. Care has to be taken that the nipples ore not shor-

ter than provided by the standards (Pic. 3).

4.

Maintentance

Disconnect from the power supply before service and repair. These jobs

should only be done by experts or authorised persons.

4.1.

Servicing

The electric threaders ROLLER’S King 1

1

/

4

and King 2 are maintenance

free. Because of a permanent grease lubrication the electric theaders

need no servicing.

4.2.

Changing of carbon brushes

The carbon brushes need to be checked for wear and replaced from

time to time. For this inspection loosen the 4 screws on the motor handle

(11) by approx. 3 mm, pull the handle towards the rear and take off the

two covers of the motor.

4.3.

Changing arresting lever (Pic. 2)

Screw out both of the slotted screws alongside the arresting lever. Re-

move arresting lever, spring and cylindrical pin. Remove burr from slot

if necessary. Re-assemble in reverse order. Check function!

4.4.

Changing dies of Central die heads

Hold die head vertically in a vice, loosen screws, remove cover, take

out dies. Knock new dies into slots vertically from above, die 1 in slot 1

etc., bevel downwards. The backs of the dies must be flush with the bo-

dy edge. Fit cover, tighten screws, at first only lightly. Knock dies with a

copper punch or a hardwood wedge until the die backs are in contact

with the cover edge.

Careful! Do not damage teeth! Now tighten screws!

4.5.

Changing dies of Rola and Rola automatik die heads

Hold die head vertically in a vice. Close tensioning stirrup, loosen

screws, lift off cover with adjusting ring and take out dies. Fit new dies,

die 1 in slot 1 and so on, die grooves upwards, bevels downwards. The

backs of the dies must be flush with she edge of the body. Fit cover with

adjusting ring. Make sure that the scale line on the edge of the cover

corresponds with the scale line on the body. Retighten screws. Check

function by opening and closing the die head a number of times.

Scale: Line on line indicates standard thread size. On the edge of the

body alongside the scale line are the marks + and –. If the cover is

turned slightly t the thread Ø becomes larger and towards –

smaller.

5.

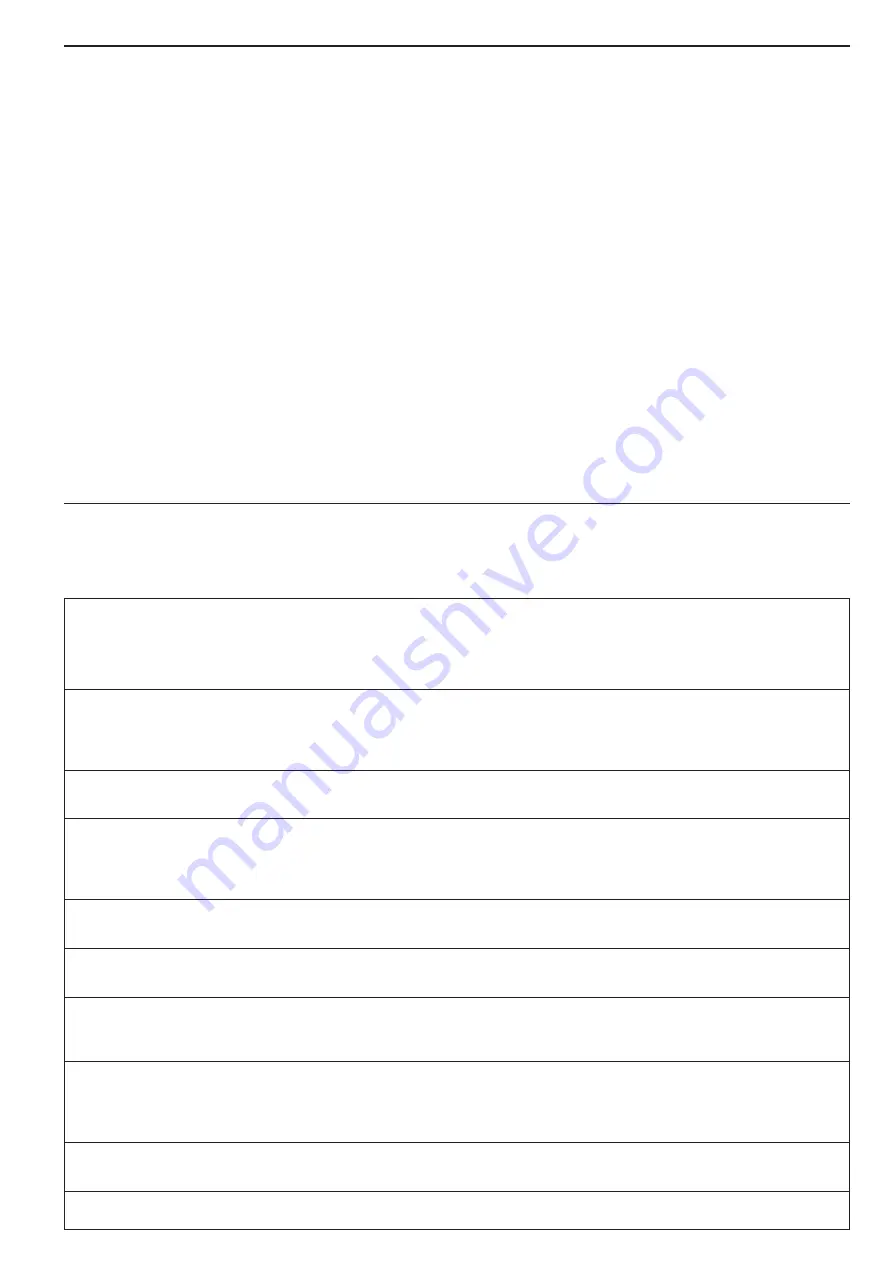

Procedure by faults

Attention! All works marked with

l

are only to be carried out by electrical specialists. Pull out mains plug!

Fault

Possible cause

Remedy

Motor does not start

Cable broken

l

Check cable

Main fuse is burned out

Replace fuse

Carbon brushes have no contact

l

Check condition and position of carbon

brushes. Replace worn brushes

Change-over switch not to the limit (8)

Push change-over switch to the limit (8)

Motor accepts no load

Short in the cable connection

l

Seek short and rectify.

Overloading through blunt dies

Replace dies

Unsuitable cuffing oil

Use ROLLER thread cutting oil

Overload disengaged

Engage overload button (10)

Abnormal overheating of motor

Overloading through blunt dies

Replace dies

Insufficient cooling air

Clean air slots in motor

Sparking in motor

Very dirty collector surface

l

Send in for repair

Carbon brushes fit badly due to excessive wear

Replace worn carbon brushes Use only

original carbon brushes.

Unsuitable brushes

l

Use original brushes

Fire ribbon in motor

Dirt particles spring from brushes or segments

l

Send in for repair

and burn out

Die head does not cut

Blunt or broken dies

Fit new dies

Rotation objection false

Check position or change-over switch

Automatik die head does not open

Dirty die guide slots

Open die head, remove dies, wash guide slots

after cutting operation

and dies with cold cleaner or paraffin.

Grease before reassembly.

Torn thread

Dies blunt

Fit new set of dies

Dies not fitted in correct order

Fit dies in correct order

Poor quality material

Observe mark of quality when buying material

Unsuitable thread cutting oil

Use ROLLER thread cutting oil

Pipe turns in support

Fine scale and dirt on the gripping

Clean with wire brush

bracket during cutting operation

jaws

Die head jams during changing

Swarf on the arresting part of die head

Remove sworf with flat file