27

5.6 COOLING DELAY PROFILES (-)H1V

The (-)H1V air handlers are shipped with a default 30 second blower OFF delay profile for

maximum efficiency.

IMPORTANT:

Blower

ON

delay profiles are not used in heating mode.

5.7 COOLING MODE DEHUMIDIFICATION (-)H1V (PASSIVE: FACTORY

PROGRAMMED PROFILES)

Factory board settings will provide general overall performance under average conditions.

Use these Advanced Profiles to optimize performance and to add soft motor operation.

Please be sure that you check for correct airflow and adjust refrigerant charge based on your

Maximum Capacity and Airflow using the Factory AIRFLOW SETTINGS. Switches 1 and 2

should be set for the tonnage and airflow requirement for the system.

Advanced Airflow set-

tings

will, in most cases, greatly reduce airflow to the system and change the system’s Latent

and Sensible capacity splits. The control board flashes CFM to the nearest 50 CFM calculat-

ed.

We suggest that trouble-shooting be done with switches in the factory position for

verification of refrigerant charge and airflow through the duct system.

TABLE 3 (-)H1V

S8

S7

S7

S8

On

On

Off

On Off

Ramp Times

CFM Reduction

5 minutes

18% Less

5 to 12.5 minutes

12% Less

after 12.5 minutes

100% Full

Operating

Sequence

Pre-programmed CFM Rates

Ramp Times

CFM Reduction

3 minutes

18% Less

after 3 minutes

100% Full

Operating

Sequence

Pre-programmed CFM Rates

Ramp Times

CFM Reduction

3 minutes

25% Less

3 to 8 minutes

12% Less

after 8 minutes

100% Full

Operating

Sequence

Pre-programmed CFM Rates

Off

S7

S8

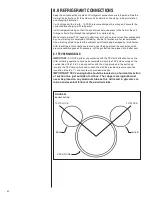

FIGURE 28

COOLING AIRFLOW ADJUSTMENTS (-)H1V

Factory

S7

on

off

on

off

S8

off

on

on

off

Moisture

Removal

Highest

Advanced Cooling Adjustments

Switch 7 and 8 Settings and Characteristics

Standard

Lowest

Good

A

OFF

OFF

800

1200

1200

1600

1800

1800

1725

B

ON

OFF

600

600

600

800

800

800

800

C

OFF

ON

800

1000

1000

1400

1600

1600

1600

D

ON

ON

600

600

600

800

800

800

800

FIGURE 27

FACTORY AIRFLOW SETTINGS FOR SWITCHES 5 AND 6 (-)H1V

SELECTION

SWITCH 5

POSITION

SWITCH 6

POSITION

(-)H1V-

2417ST

(-)H1V-

3617ST

(-)H1V-

3821ST

3621H

(-)H1V-

4824ST

4821M

(-)H1V-

4824ST

(-)H1V-

6024ST

(-)H1V-

6021S

ELECTRIC HEAT AIR FLOW

O

N

O

N

O

N

O

N

A

B

C

D

5

6

5

6

5

6

5

6

MINIMUM AIR FLOW PER kW

3 kW to 13 kW

=

600 min. CFM

15 kW to 18 kW

=

800 min. CFM

20 kW to 25 kW

=

1400 min. CFM

30 kW

=

1800 min. CFM

Содержание RH1V2417STANJA

Страница 54: ...54 FIGURE 44 COMFORT CONTROL2 SYSTEM AIR HANDLER WIRING DIAGRAM H2V...

Страница 55: ...55...

Страница 56: ...56 CM 0115...